Upgrading factory electrical systems is essential for enhancing performance and ensuring safety. This process involves augmenting power handling and transmission capacities to boost production and conserve energy.

Objectives for Enhancing Performance and Optimizing Energy

The goal of upgrading factory electrical systems is to enhance performance by boosting energy transmission capacity and minimizing unnecessary downtime. Furthermore, optimizing energy usage is crucial to reducing waste and improving technology to meet new energy demands in industrial systems.

Amid modern industrialization, goals of energy optimization and performance enhancement are pivotal for businesses to maintain competitiveness and sustainable growth. Energy optimization not only cuts costs but also helps in environmental protection, meeting new demands. To achieve these goals, various solutions have been implemented.

- Energy Audit: This is the initial step to specifically identify energy waste within the system. Through audits, businesses can proactively recognize and apply more effective energy management measures, reducing losses.

- Investing in Energy-Saving Equipment: Replacing outdated, inefficient equipment with modern models like IE3 or IE4 motors boosts electrical efficiency, lowers energy consumption, and extends equipment lifespan.

- Implementing Smart Manufacturing: Utilizing IoT technology for automation and optimization of production processes minimizes energy usage through continuous data analysis and timely adjustments.

- Optimizing Production Processes: Streamlining and eliminating unnecessary steps in the production process to achieve the best energy efficiency.

Energy optimization benefits are diverse:

- Cut Energy Costs: More efficient operations mean lower electricity costs.

- Increase Production Efficiency: Boost capacity without increasing investment resources, while also enhancing product quality.

- Environmental Protection: Reducing carbon emissions helps protect a green, clean, beautiful environment.

- Sustainable Development: Ensuring long-term growth focusing on green growth and resource saving.

Strategies and policies have also been established to guide businesses:

- Support for High-Performance Product Development: Encouraging the development and application of energy-saving products globally.

- Enhancing State Management: Strict regulations in energy management promote efficient resource use.

- Digitalization and Advanced Technology: Employing new technologies like IoT to accurately control energy use in production and consumption activities.

Process for Upgrading Factory Electrical Systems

The process of upgrading electrical systems begins with surveying and assessing the current state, followed by crafting a detailed plan. Implementation is carried out based on this plan with strict safety compliance. After new device installations, the system undergoes thorough testing before handover. Periodic maintenance is crucial to ensure electrical efficiency and safety.

Upgrading factory electrical systems is an important process to ensure safety, reliability, and efficiency in industrial production. This process is executed through major stages, from initial condition assessment and new system design to execution and regular maintenance.

The initial step is condition assessment and planning. This phase includes surveying the current state of the electrical system, identifying weaknesses or gaps impacting safety and efficiency. Next is analyzing power demand, stability, and future expansion potential to create a comprehensive upgrade plan.

New electrical system design is a critical phase, involving drawing detailed plans to meet safety standards, reliability, and future scalability. This plan aids in selecting suitable electrical equipment such as transformers from ABB, Mitsubishi, or devices from Eaton, Schneider. Additionally, compiling a detailed cable schedule is an essential step.

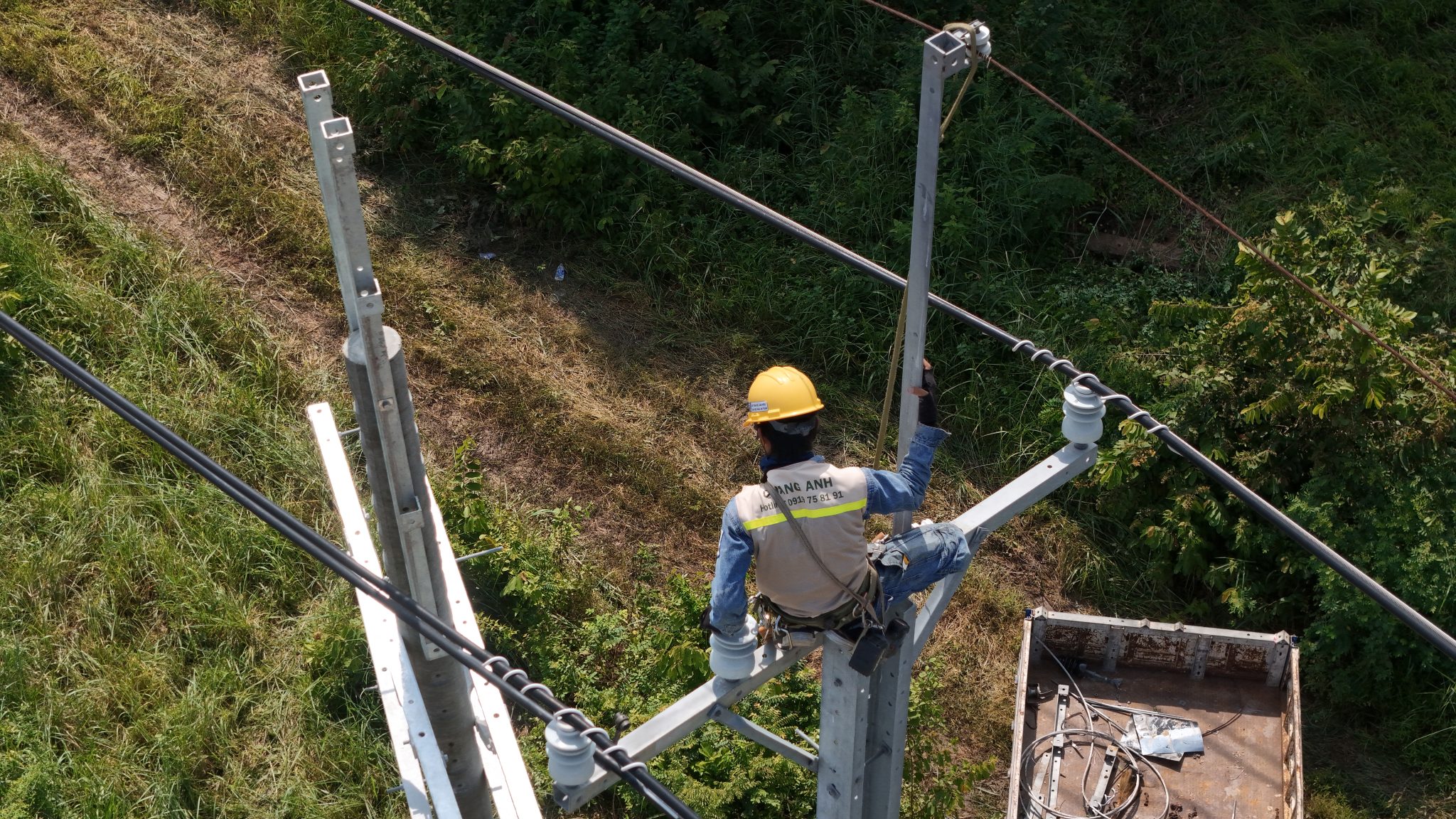

Execution, installation, and system upgrade are decisive phases of the project, involving preparing quality materials like Cadivi cables, installing power cables and distribution cabinets, adhering strictly to electrical safety standards and technical depth.

Post-installation, rigorous testing and trial operations check system safety and efficiency. This includes testing the entire system, conducting load trials and endurance checks, identifying and addressing issues before project handover.

Finally, periodic maintenance is essential to maintain stable operational efficiency and preemptively address potential issues before they escalate. Maintenance ensures not only electrical safety but also long-term operational cost optimization. Post-upgrade performance evaluations assist in planning future enhancements.

Factory electrical system upgrades not only bring operational stability and safety but also cost savings and improved industrial production quality.

Key Elements in Electrical System Upgrades

Calculating capacity is crucial for ensuring electrical demand is met when upgrading systems. Providing compatible and efficient equipment is a top priority. Electrical safety cannot be overlooked, requiring adherence to safety regulations throughout the upgrade and maintenance processes.

To meet the rising energy demands while ensuring system efficiency and safety, upgrading electrical systems is imperative. Key elements to consider include:

1. Rising Energy Demand

- Economic and Population Growth: Economic development and population growth create higher electricity demand, necessitating appropriate system upgrades to meet these requirements.

- Shift to Renewable Energy: Integrating renewable energy sources like solar and wind reduces reliance on traditional energy, essential for sustainable development.

2. Overload and Safety

- Electrical Overload: Increased power consumption can lead to overloads, causing outages or voltage drops. Upgrading ensures more stable and safer system operation.

- Electrical Safety: Upgrades must ensure updated equipment and technology to avoid safety risks from outdated devices.

3. Project Quality and Efficiency

- Ensuring Project Quality: To maintain system safety and optimal efficiency, the quality of installation and upgrade projects must be closely checked.

- Integration of Modern Energy Technology: Advanced technologies from brands like ABB, Mitsubishi, or Schneider can enhance system performance and reliability.

4. Comprehensive Electrical System Development

- Ensuring a diverse power source to meet usage needs.

- Optimizing distribution and rational electricity use.

- Ensuring stable and reasonable power pricing.

5. Measurement and Protection Systems

- Utilizing modern measurement and protection systems from Eaton or LS helps in early incident detection and handling, ensuring comprehensive electrical safety.

These factors must be carefully considered to ensure the system not only meets current needs but is also future-proof.

Upgrading factory electrical systems yields numerous technical benefits, enhancing efficiency and reducing risks, laying the groundwork for sustainable investment and improving competitiveness.

Contact QuangAnhcons via Hotline: +84 9 1975 8191 for expert guidance on efficiently and safely upgrading your factory electrical systems.

QuangAnhcons offers high-expertise upgrading services for factory electrical systems, optimizing energy and ensuring safety, from surveying and design to execution and maintenance.

[contact-form-7 id="7239967" title="Contact form 1"]

Related Posts

Tay Ninh Solar Power Planning: Technical Framework, Grid Interconnection, and Rollout Roadmap

Technical overview of solar planning in Tay Ninh: irradiation, grid capacity, permitting, design, operations, and [...]

Dec

Binh Duong Solar Planning: Regulatory Framework, Grid Interconnection, and an Implementation Roadmap for Factories and Industrial Parks

An overview of Binh Duong solar planning: legal framework, interconnection, design, risk management, and an [...]

Dec

Solar Farm Repair: O&M Workflow, IV Curve Diagnostics, Thermography, Inverter Service and Utility-Scale Safety

A utility-scale solar farm repair plan centered on O&M, IV curves, thermal imaging, inverter service, [...]

Dec

Dong Nai Solar Power Plan 2023–2025: Tri An 1,029 MW, Grid Upgrades and the DPPA Pathway

A complete look at Dong Nai’s solar power plan: Tri An 1,029 MW, irradiation potential, [...]

Nov

Quang Ngai Solar Power Plan 2024–2030: Legal Framework, Irradiance Potential, and Development Roadmap

A complete look at Quang Ngai’s solar power plan: capacity targets, irradiance (PVout), development zones, [...]

Nov

Solar Damage Assessment Services: On-Site Procedures, EL/IV/Thermography Testing & Compliance with Standards

Discover IEC/UL/NEC standard solar damage assessment processes: on-site evaluation, EL and IV curve testing, thermal [...]

Nov

Comprehensive Package Estimate for a 1800MVA 500kV Substation: Scope, Configuration 3x600MVA, Standards and Timeline Management

An overview of the 1800MVA 500kV substation estimate: construction scope, configuration 3x600MVA, GIS/AIS, SCADA, standards, [...]

Nov

Factory Electrical Systems: Comprehensive Design and Implementation Guide

Discover the detailed and safe process of factory electrical systems design and implementation. [...]

Oct

Blueprints Required for Factory Construction Permits

Discover the necessary blueprints in factory construction permit applications, from floor plans to electrical and [...]

Oct

What Are the Requirements for a Factory Construction Permit? A Comprehensive Guide

Explore the documentation and steps needed to secure a factory construction permit for streamlined project [...]

Oct

Factory Construction Permit Procedures in Vietnam: Essential Guidelines and Documents

Learn the procedures for securing a factory construction permit in Vietnam, focusing on document preparation [...]

Oct

Key Steps in the Factory Construction Process

Discover the essential steps and requirements for building factories. [...]

Oct

Comprehensive Electrical Substation Solutions by Quanganhcons

Discover the cutting-edge electrical substation solutions offered by Quanganhcons for industrial applications. [...]

Oct

Investment Costs for a 1MWp Solar Power System and Influencing Factors

Explore the investment costs for a 1MWp solar power system in Vietnam and the influencing [...]

Sep

QuangAnhcons: Elevating Wind Energy Solutions

Explore QuangAnhcons' leadership in wind energy and renewable solutions in Vietnam. [...]

Sep

Electrical Contractor Strategies at Becamex Industrial Park

Discover the strategic advancements and partnerships of the electrical contractor at Becamex Industrial Park. [...]

Sep

Investment Insights for 1MW Wind Energy in Vietnam: Costs and Opportunities

Discover the detailed analysis of costs and opportunities for investing in 1MW wind energy projects [...]

Sep

Advanced Electrical Installation Solutions by QuangAnhcons

Explore advanced electrical installation solutions and modern technology with QuangAnhcons. [...]

Sep

Enhancing Industrial Electrical Services with Quanganhcons

Discover Quanganhcons' expertise in industrial electrical services, offering efficient and sustainable power systems. [...]

Sep

Comprehensive MEP Solutions by QuangAnhcons: From Design to Maintenance Excellence

Discover optimal MEP solutions with QuangAnhcons, dedicated to excellence from design through maintenance. [...]

Sep