Quang Anh Construction Co., Ltd. offers professional transformer repair services in Long An, addressing power outages and implementing new transformer stations with quality and safety assurance.

In-depth Transformer Repair Process

QuangAnhcons’ transformer repair process in Long An features detailed steps including inspection, coil cleaning, oil tank care, and testing. Each component such as coils, magnetic cores, valves, and bushings undergo rigorous evaluation to meet the highest technical standards.

Repairing transformers is crucial for electrical system efficiency and safety. This process is typically divided into three main stages to meet these requirements.

1. Minor Maintenance

- Focus on external inspections and minor repairs without oil drainage or internal access.

- Cleaning the casing, bushings, and removing impurities from auxiliary oil tanks; adding oil and cleaning sight tubes as necessary.

- Replacing silica gel in breather tanks and inspecting valves, gaskets, cooling systems, and essential protection devices.

2. Scheduled Overhaul

- Scheduled transformer overhauls involve power shutdowns and core extraction for comprehensive inspections.

- Recording technical parameters and reviewing operational records to identify areas needing attention.

- Cleaning, drying the core to restore insulation, checking components like magnetic cores, coils, and cooling systems.

- Testing technical parameters to standards after the overhaul.

3. Full Restoration

- Restoration involves repairing or replacing coils and inter-laminar insulation.

- Ensuring optimal operation of cooling, protection systems, and mechanical structures.

Routine Maintenance

- Includes 3, 6, or 12-month periodic inspections, oil sampling, and cleaning alongside tap changer and protection system checks.

- For dry transformers, additional dust removal and moisture control are essential for longevity.

This maintenance and repair framework is designed to minimize operational failures, extend equipment life, and ensure optimal performance.

Maintenance and Servicing of Transformers

The maintenance and servicing of transformers is an integral component of QuangAnhcons’ repair services in Long An. Ensuring optimal equipment durability, QuangAnhcons offers a comprehensive range of maintenance services to enhance system performance.

Transformer maintenance involves complex technical procedures intended to optimize operational efficiency and extend the transformer’s lifespan. Standard activities include high and low voltage cable inspections, magnetic core cleaning, and tasks such as terminal tightening, insulation checks, and system control tests to ensure stable operation.

Maintenance cycles are clearly timed, with periodic checks every 3 months and comprehensive maintenance every 6 months. Overhaul services, necessary every 8-12 years, encompass thorough oil draining, filtering, and core drying following technical standards. Post-overhaul testing is vital to ensure operational safety and efficiency.

Maintenance specifics vary by transformer type. Oil transformers require cleaning the entire station and securing station foundations, while dry transformers involve moisture removal with vacuum processes and making sure connections remain tight to prevent damage.

Daily maintenance involves checking oil levels via MOG, addressing leaks, and changing silica gel upon color change. These activities not only maintain optimal transformer performance but also prevent potential issues.

Effective maintenance services provide reliability and safety for these essential electrical devices.

Handling Emergencies and New Transformer Station Construction

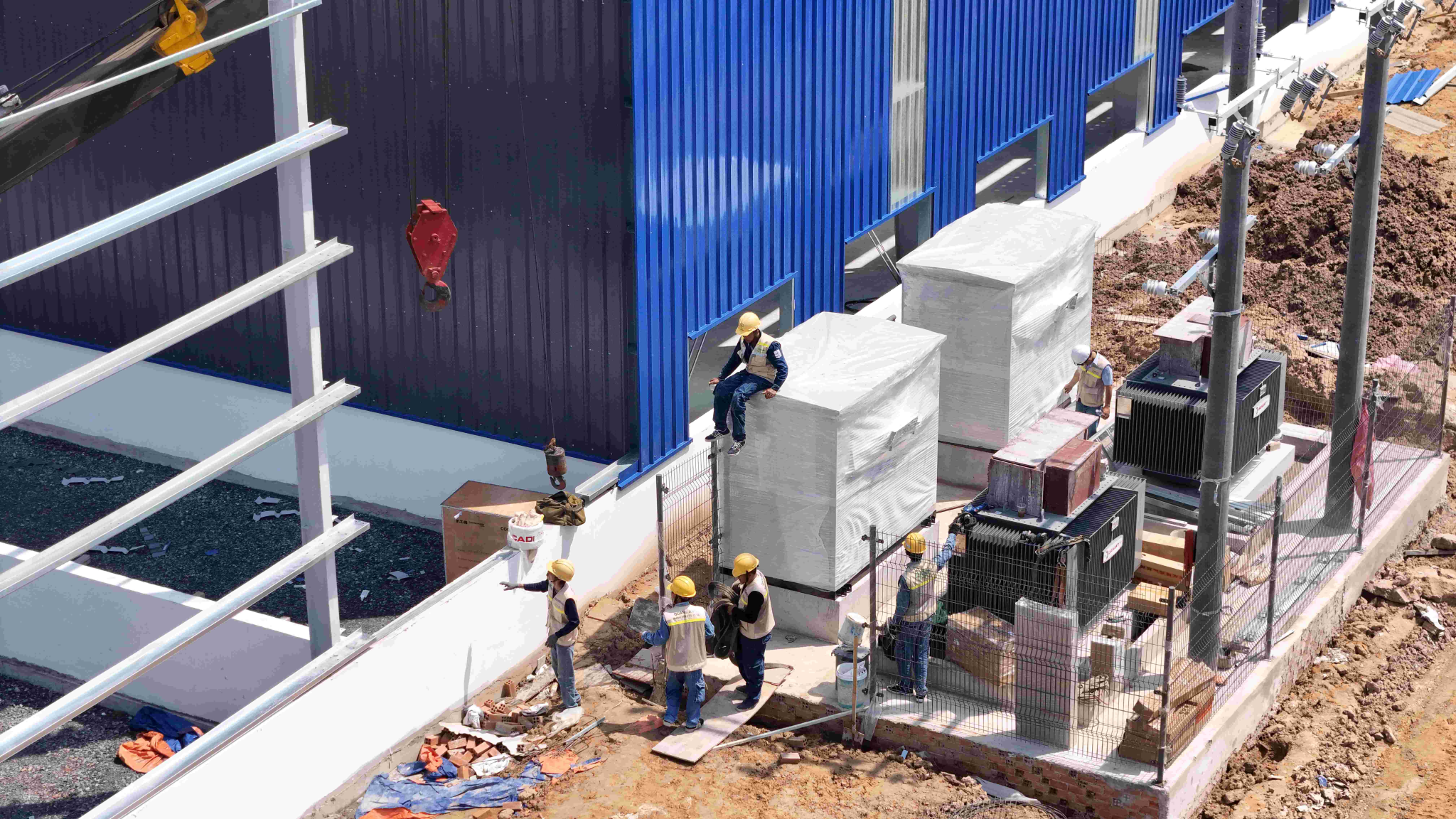

In cases of severe transformer faults, QuangAnhcons offers emergency handling and new transformer station construction services in Long An. Projects like the 2500KVA station at Long Hau Industrial Park exemplify their commitment to timely, quality work, underpinning industrial electrical stability and sustainable growth.

New station construction and troubleshooting adhere to modern technical standards, ensuring safety and superior quality. Building a transformer station involves a meticulous process from site surveying to commissioning and handover to ensure system effectiveness.

- Site Survey and Station Design:

- Technicians must conduct site surveys to choose a suitable location for foundation building and medium voltage cabling, requiring consensus between the investor and stakeholders to fit technical plans.

- Ground Preparation and Foundation Construction:

- Pinpointing and excavating foundations according to design drawings, maintaining dry foundations. Concrete pouring standards must be stringently followed to ensure worker safety.

- Installing Grounding Systems and Electrical Equipment:

- Installing lightning protection systems along with medium and low voltage equipment, ensuring proper technical installation to protect the station from electrical faults.

- Transformer Station Installation:

- Following manufacturer guidelines, such as those from ABB, Mitsubishi, or EEMC, to ensure synchronized operation of protective devices and automatic switches during installation.

- Medium Voltage Cabling, Connection, and Finalization:

- Medium voltage cable connection to integrate the station into the existing network, installing warning signs to maintain system safety.

- Experimentation, Adjustment, Commissioning, and Handover:

- Conduct technical tests, commissioning, trial power supply, and handover to commence official system operation.

Emergency management for transformer stations primarily includes:

-

Fault Inspection and Cause Identification:

-

Assessing through measurement and testing to identify root causes like overloading or protective device failures.

-

Safety Measures Execution:

-

Implementing power cuts and isolating faulty devices to prevent escalation.

-

Technical Fault Management:

-

Repairing or replacing faulty devices and adjusting systems to meet standards before restoring power supply.

-

System Inspection Post-Repair:

-

Ensuring restored transformer station stability.

Constructing and operating transformer stations must strictly adhere to safety regulations, ensuring efficient electrical system management and operation.

QuangAnhcons’ transformer repair services in Long An prioritize swift emergency response along with precise and effective technical procedures. This strategic investment safeguards system safety and longevity.

Contact QuangAnhcons at +84 9 1975 8191 for expert transformer repair services in Long An.

QuangAnhcons provides comprehensive transformer repair, maintenance, and servicing in Long An, committed to advanced technology and safety with a team of professional engineers.

[contact-form-7 id="7239967" title="Contact form 1"]

Related Posts

Tay Ninh Solar Power Planning: Technical Framework, Grid Interconnection, and Rollout Roadmap

Technical overview of solar planning in Tay Ninh: irradiation, grid capacity, permitting, design, operations, and [...]

Dec

Binh Duong Solar Planning: Regulatory Framework, Grid Interconnection, and an Implementation Roadmap for Factories and Industrial Parks

An overview of Binh Duong solar planning: legal framework, interconnection, design, risk management, and an [...]

Dec

Solar Farm Repair: O&M Workflow, IV Curve Diagnostics, Thermography, Inverter Service and Utility-Scale Safety

A utility-scale solar farm repair plan centered on O&M, IV curves, thermal imaging, inverter service, [...]

Dec

Dong Nai Solar Power Plan 2023–2025: Tri An 1,029 MW, Grid Upgrades and the DPPA Pathway

A complete look at Dong Nai’s solar power plan: Tri An 1,029 MW, irradiation potential, [...]

Nov

Quang Ngai Solar Power Plan 2024–2030: Legal Framework, Irradiance Potential, and Development Roadmap

A complete look at Quang Ngai’s solar power plan: capacity targets, irradiance (PVout), development zones, [...]

Nov

Solar Damage Assessment Services: On-Site Procedures, EL/IV/Thermography Testing & Compliance with Standards

Discover IEC/UL/NEC standard solar damage assessment processes: on-site evaluation, EL and IV curve testing, thermal [...]

Nov

Comprehensive Package Estimate for a 1800MVA 500kV Substation: Scope, Configuration 3x600MVA, Standards and Timeline Management

An overview of the 1800MVA 500kV substation estimate: construction scope, configuration 3x600MVA, GIS/AIS, SCADA, standards, [...]

Nov

Factory Electrical Systems: Comprehensive Design and Implementation Guide

Discover the detailed and safe process of factory electrical systems design and implementation. [...]

Oct

Blueprints Required for Factory Construction Permits

Discover the necessary blueprints in factory construction permit applications, from floor plans to electrical and [...]

Oct

What Are the Requirements for a Factory Construction Permit? A Comprehensive Guide

Explore the documentation and steps needed to secure a factory construction permit for streamlined project [...]

Oct

Factory Construction Permit Procedures in Vietnam: Essential Guidelines and Documents

Learn the procedures for securing a factory construction permit in Vietnam, focusing on document preparation [...]

Oct

Key Steps in the Factory Construction Process

Discover the essential steps and requirements for building factories. [...]

Oct

Comprehensive Electrical Substation Solutions by Quanganhcons

Discover the cutting-edge electrical substation solutions offered by Quanganhcons for industrial applications. [...]

Oct

Investment Costs for a 1MWp Solar Power System and Influencing Factors

Explore the investment costs for a 1MWp solar power system in Vietnam and the influencing [...]

Sep

QuangAnhcons: Elevating Wind Energy Solutions

Explore QuangAnhcons' leadership in wind energy and renewable solutions in Vietnam. [...]

Sep

Electrical Contractor Strategies at Becamex Industrial Park

Discover the strategic advancements and partnerships of the electrical contractor at Becamex Industrial Park. [...]

Sep

Investment Insights for 1MW Wind Energy in Vietnam: Costs and Opportunities

Discover the detailed analysis of costs and opportunities for investing in 1MW wind energy projects [...]

Sep

Advanced Electrical Installation Solutions by QuangAnhcons

Explore advanced electrical installation solutions and modern technology with QuangAnhcons. [...]

Sep

Enhancing Industrial Electrical Services with Quanganhcons

Discover Quanganhcons' expertise in industrial electrical services, offering efficient and sustainable power systems. [...]

Sep

Comprehensive MEP Solutions by QuangAnhcons: From Design to Maintenance Excellence

Discover optimal MEP solutions with QuangAnhcons, dedicated to excellence from design through maintenance. [...]

Sep