Transformer oil filtration refines insulating oil by removing water, dissolved gases, and impurities, thereby preserving and enhancing electrical insulation and heat dissipation properties, maintaining transformer quality and performance.

Mechanism of Transformer Oil Filtration and Its Importance

Transformer oil filtration is the process of treating the insulating oil in transformers to eliminate impurities such as water, dissolved gases, and solid particles. This not only protects but also boosts the oil’s insulating and cooling capabilities. Therefore, oil filtration aids in maintaining and improving oil quality, ensuring the transformer’s performance and lifespan. Filtration is executed using a system featuring inlet globe valves, primary filters, oil heaters, and automated control devices.

In construction and energy sectors, transformer oil filtration is crucial for maintaining and protecting transformers. The filtration mechanism works through a complex procedure to completely eradicate impurities including dirt, moisture, and dissolved gases in the insulating oil. Transformer maintenance demands a stringent filtration process, starting with coarse filtration to remove large particles, a vital step for improving insulation and heat dissipation effectiveness.

Subsequently, the oil filtration system uses a heater to raise the oil temperature to approximately 40-80°C, enhancing filtration efficiency. Upon reaching the desired temperature, a vacuum pump extracts dissolved gases and water, allowing water to evaporate and condense in the water separation tank before discharge. Finally comes fine filtration, removing minute impurities and metals or oxides through magnetic or adsorptive filters. Components like inlet valves, gear pumps, and measurement systems efficiently oversee and control this procedure.

Filtration systems facilitate not only the recycling of used insulating oil but also reduce costs and environmental impacts. Transformer oil filtration is indispensable for ensuring safe transformer operation, acting against failures like overheating or short circuits due to accumulated impurities. Reputable brands such as ABB and Mitsubishi offer advanced filtration equipment tailored to the specific needs of various electrical systems.

Regular oil filtration helps businesses not only secure system performance but also prolong transformer life, optimizing both economic and technical advantages across entire electrical systems.

Benefits of Transformer Oil Filtration: Boosting Efficiency and Longevity

The primary goal of transformer oil filtration is to remove moisture, insoluble impurities, and dissolved gases, thereby enhancing the oil’s insulating properties while safeguarding the internal paper insulation of the transformer. Unfiltered transformer oil risks oxidation, leading to oxides, acids, and sludge, negatively affecting equipment operation. Modern filtration systems often include dehydration functions to ensure complete water removal, enhancing overall efficiency.

Transformer oil filtration plays a pivotal role in maintaining effective equipment operations and extending transformer lifespan. This process eliminates dirt, water, and dissolved gases such as CO, CO2, O2, H2, thereby improving insulating oil quality, contributing to heightened efficiency and durability of the transformer.

Impact of Impurities on Transformer Oil

Transformer oil serves dual purposes of cooling and insulating. Contamination by impurities such as water, dirt, or oxidation reduces its insulating capabilities significantly. This deterioration can damage the internal insulation layers of the transformer by diminishing electrical strength, increasing the risk of equipment failure.

Oil Filtration Process

The oil filtration process employs specialized devices equipped with vacuum and heating systems. This system effectively removes impurities larger than 5 microns while also extracting water and dissolved gases. Post-filtration, the oil’s dielectric breakdown voltage can improve significantly, from 30kV up to 60-80kV, reduces moisture content in the oil, and markedly enhances equipment efficiency.

Advantages of Transformer Oil Filtration

By eliminating components that degrade the oil’s insulating properties, transformers operate more smoothly, reducing failure risks, improving efficiency, and extending equipment lifespan. High-capacity oil filtration machines, capable of handling thousands of liters per hour, are ideal for processing oil for high-voltage transformers and large industrial equipment, adhering to rigorous operational standards.

Transformer oil filtration is an essential step in equipment maintenance and operation, ensuring the oil’s physical, chemical, and insulating properties are maintained at optimal levels. Renowned brands, such as ABB and Mitsubishi, offer modern oil filtration equipment ensuring transformers operate effectively under varied conditions.

Efficient Operation of Transformer Oil Filtration Systems

The operation of a transformer oil filtration system encompasses steps such as opening valves and running oil pumps to expel gases and impurities, heating oil to enhance filtration efficiency, using a vacuum pump to condense and eliminate water, and circulating oil through coarse and fine filters to ensure complete purification before returning it to the transformer. This process effectively removes all impurities that could reduce transformer performance.

Initial Set-Up and Preparation Steps

Operating a transformer oil filtration system starts with the preparation and setting of key operational parameters. Initially, the vacuum gauge should be set between -0.07 and -0.09 Mpa. The temperature control is set from 45-65°C to ensure adequate oil heating for effective system operation.

Operational Process of the Filtration System

- Gradually open air release valves until the oil is full, with no gases present in the conduit.

- Start the transformer vacuum pump to test vacuum pressure before opening the solenoid valve for oil delivery into the filtration system. Transformer oil passes through primary, magnetic, and fine filters under low pressure to eliminate impurities and moisture.

Automated Monitoring and Control

The automatic control system allows for precise oil level management in the storage tank. The oil level sensor activates the output solenoid valve and recirculation pump when the oil level reaches the lower limit, while the fill valve closes when the upper limit is reached, ensuring stable operation and avoiding oil shortages.

Quality Inspection and Monitoring Post-Filtration

After completing transformer oil filtration through multiple circulation rounds within the system, oil quality is inspected and analyzed. Ensuring the oil standard meets technical requirements before returning it into transformer operations.

Critical Operational Notes

To maintain optimal operation:

- Position the filtration machine near the transformer or oil tank for short, sealed oil conduits.

- During oil transfer, the transformer should be halted to ensure safety and efficiency.

Transformer oil filtration is essential in maintenance and ensuring peak performance for electrical equipment, removing elements that degrade oil features, and prolonging transformer lifespan. Investing in modern oil filtration systems is both technically and financially astute.

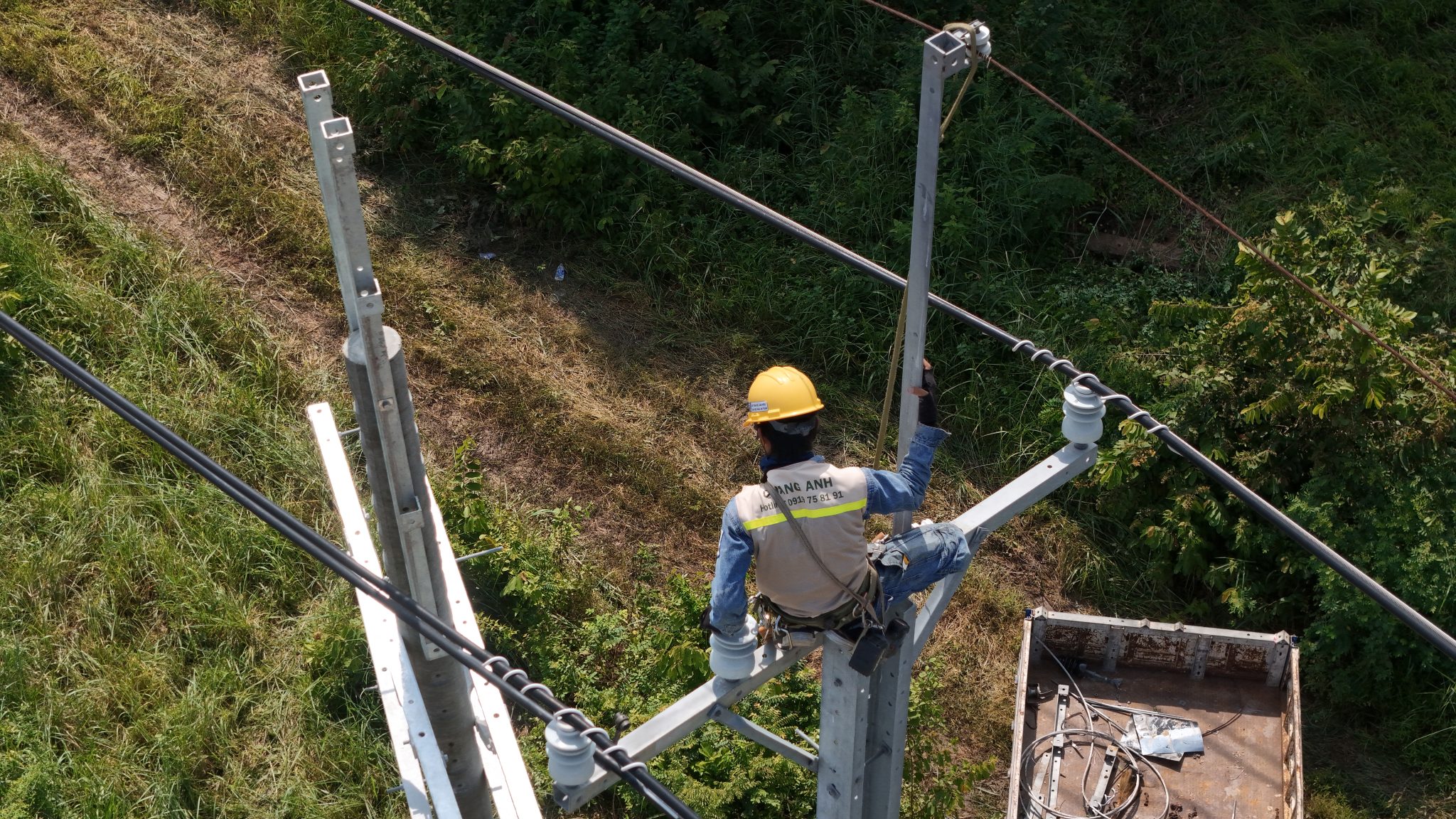

Discover QuangAnhcons’ transformer oil filtration services to maintain and enhance your electrical equipment’s performance. Contact us via hotline: +84 9 1975 8191 for consultation.

QuangAnhcons offers professional and effective transformer oil filtration services, removing impurities and protecting your transformers, guaranteeing quality and sustainability for your electrical power system.

[contact-form-7 id="7239967" title="Contact form 1"]

Related Posts

Tay Ninh Solar Power Planning: Technical Framework, Grid Interconnection, and Rollout Roadmap

Technical overview of solar planning in Tay Ninh: irradiation, grid capacity, permitting, design, operations, and [...]

Dec

Binh Duong Solar Planning: Regulatory Framework, Grid Interconnection, and an Implementation Roadmap for Factories and Industrial Parks

An overview of Binh Duong solar planning: legal framework, interconnection, design, risk management, and an [...]

Dec

Solar Farm Repair: O&M Workflow, IV Curve Diagnostics, Thermography, Inverter Service and Utility-Scale Safety

A utility-scale solar farm repair plan centered on O&M, IV curves, thermal imaging, inverter service, [...]

Dec

Dong Nai Solar Power Plan 2023–2025: Tri An 1,029 MW, Grid Upgrades and the DPPA Pathway

A complete look at Dong Nai’s solar power plan: Tri An 1,029 MW, irradiation potential, [...]

Nov

Quang Ngai Solar Power Plan 2024–2030: Legal Framework, Irradiance Potential, and Development Roadmap

A complete look at Quang Ngai’s solar power plan: capacity targets, irradiance (PVout), development zones, [...]

Nov

Solar Damage Assessment Services: On-Site Procedures, EL/IV/Thermography Testing & Compliance with Standards

Discover IEC/UL/NEC standard solar damage assessment processes: on-site evaluation, EL and IV curve testing, thermal [...]

Nov

Comprehensive Package Estimate for a 1800MVA 500kV Substation: Scope, Configuration 3x600MVA, Standards and Timeline Management

An overview of the 1800MVA 500kV substation estimate: construction scope, configuration 3x600MVA, GIS/AIS, SCADA, standards, [...]

Nov

Factory Electrical Systems: Comprehensive Design and Implementation Guide

Discover the detailed and safe process of factory electrical systems design and implementation. [...]

Oct

Blueprints Required for Factory Construction Permits

Discover the necessary blueprints in factory construction permit applications, from floor plans to electrical and [...]

Oct

What Are the Requirements for a Factory Construction Permit? A Comprehensive Guide

Explore the documentation and steps needed to secure a factory construction permit for streamlined project [...]

Oct

Factory Construction Permit Procedures in Vietnam: Essential Guidelines and Documents

Learn the procedures for securing a factory construction permit in Vietnam, focusing on document preparation [...]

Oct

Key Steps in the Factory Construction Process

Discover the essential steps and requirements for building factories. [...]

Oct

Comprehensive Electrical Substation Solutions by Quanganhcons

Discover the cutting-edge electrical substation solutions offered by Quanganhcons for industrial applications. [...]

Oct

Investment Costs for a 1MWp Solar Power System and Influencing Factors

Explore the investment costs for a 1MWp solar power system in Vietnam and the influencing [...]

Sep

QuangAnhcons: Elevating Wind Energy Solutions

Explore QuangAnhcons' leadership in wind energy and renewable solutions in Vietnam. [...]

Sep

Electrical Contractor Strategies at Becamex Industrial Park

Discover the strategic advancements and partnerships of the electrical contractor at Becamex Industrial Park. [...]

Sep

Investment Insights for 1MW Wind Energy in Vietnam: Costs and Opportunities

Discover the detailed analysis of costs and opportunities for investing in 1MW wind energy projects [...]

Sep

Advanced Electrical Installation Solutions by QuangAnhcons

Explore advanced electrical installation solutions and modern technology with QuangAnhcons. [...]

Sep

Enhancing Industrial Electrical Services with Quanganhcons

Discover Quanganhcons' expertise in industrial electrical services, offering efficient and sustainable power systems. [...]

Sep

Comprehensive MEP Solutions by QuangAnhcons: From Design to Maintenance Excellence

Discover optimal MEP solutions with QuangAnhcons, dedicated to excellence from design through maintenance. [...]

Sep