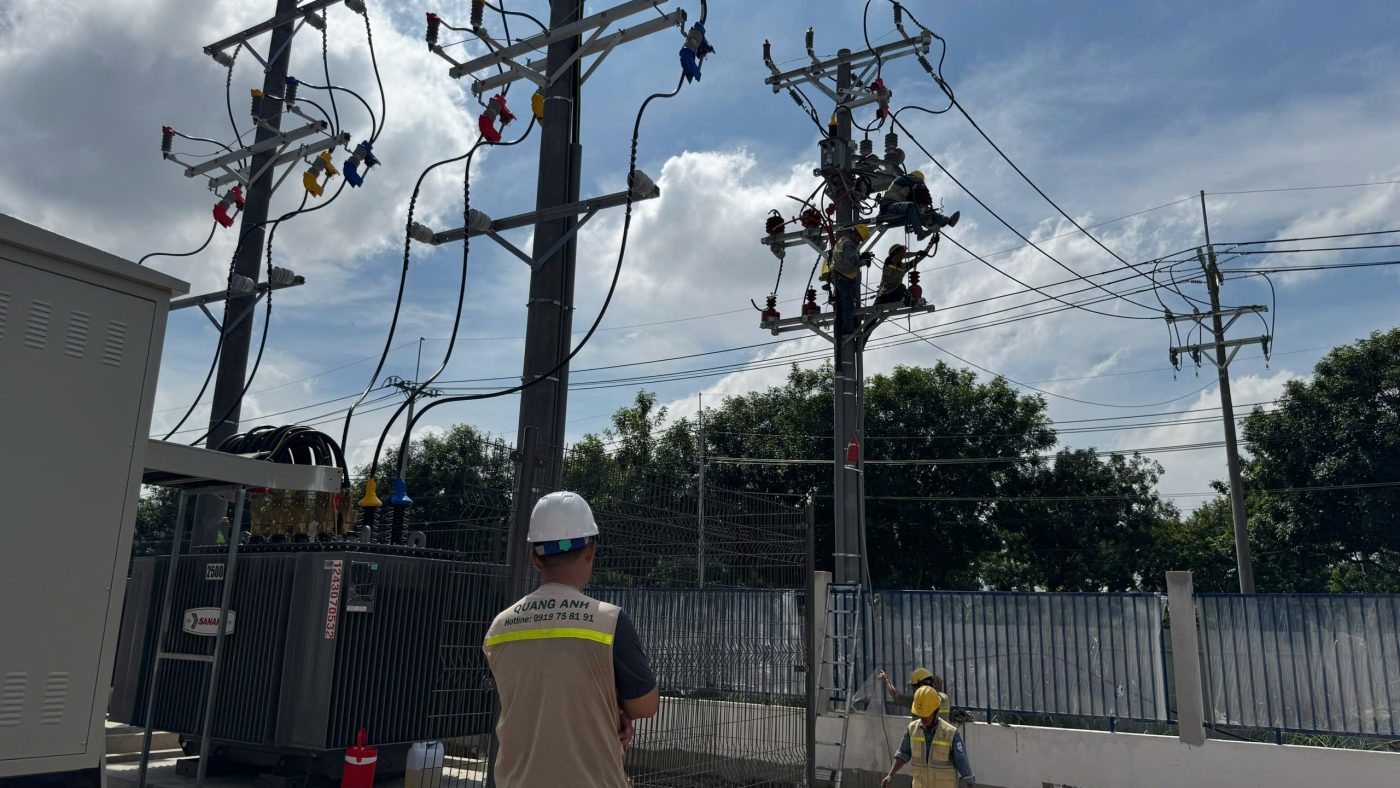

In Can Tho, Quanganhcons specializes in offering repair and construction services for transformers, medium and low voltage electrical systems, and substations up to 35kV. The company ensures high operational efficiency by utilizing precisely sourced equipment and professional processes.

Transformer Repair Services

Transformer Repair Services

Quanganhcons provides transformer repair services, strictly using materials with guaranteed provenance. With a focus on repairing transformers and industrial electrical equipment, the company ensures optimal operational efficiency. They are capable of surveying, testing transformer oil, and inspecting related electrical devices, catering to factories and industrial zones in Can Tho.

Transformer repair services are vital for maintenance and performance enhancement, including repair levels such as minor, routine, and restorative overhauls.

Minor Repairs

Minor repairs involve inspections and small fixes without dismantling the entire transformer. This typically includes cleaning the outer casing and parts, draining residual oil, and inspecting components like gaskets, valves, cooling systems, and lightning protection. Replacing moisture-absorbing materials such as silica gel also ensures stability.

Routine Overhaul

Routine overhaul involves disassembling for comprehensive inspection and repair inside the transformer. The process might include drying the transformer to enhance insulation and ensure components work synchronously, which is crucial for maintaining transformer efficiency.

Restorative Overhaul

Restorative overhaul focuses on severe damages, such as rewinding or replacing faulty coils, repairing the iron core, and restoring insulation on laminations. This stage is essential to bring the transformer back to optimal condition and ensure sustainable operation.

The transformer repair process comprises steps like disconnecting the power supply, draining the oil, dismantling to access the faulty parts, undertaking required repairs or replacements, followed by performance tests like checking winding ratios, insulation resistance, oil resistivity, and load testing. These steps ensure safe and standard transformer operation.

In addition to repair services, regular maintenance is necessary to sustain transformer performance. This involves inspecting and cleaning components such as gaskets, insulators, and welds, along with oil sampling for quality analysis. Maintenance also includes servicing the tap changer and addressing moisture causes, especially in dry transformers.

Proper transformer repair and maintenance techniques help reduce the risk of major failures and prolong equipment life, ensuring optimal performance for industrial and distribution electrical systems.

Substation and Electrical System Construction

Quanganhcons provides complete construction of substations up to 35kV, including suspended, gantry, single-pole steel, foundation, and modular kiosks substations. The company uses oil-filled and dry transformers from reputable brands like Siemens and ABB, with full certification and approval from the electrical industry.

Constructing substations and electrical systems is a complex process requiring high precision to ensure safety and efficient operation. Based on credible technical studies, this process includes crucial steps:

-

Site Survey and Construction Planning: The initial stage involves terrain inspection, evaluating locations for substation installation and medium-voltage underground cables. Experienced technicians conduct surveys, set precise benchmarks, and coordinate design changes with investors if necessary ([1], [2], [3]).

-

Materials Preparation and Quality Check: This crucial step ensures transformers, switches, and insulators meet technical standards before installation ([3]).

-

Substation Foundation and Underground System Construction:

- Excavating for the substation foundation and medium-voltage underground cable trench.

- Installing grounding systems, classifying, and ensuring safety (protective grounding, lightning discharge grounding, and functional grounding) ([1], [4]).

-

Installation and Securing Station Equipment: Precision is required when setting concrete foundations, installing transformers, switches, operating platforms, and pulling medium-voltage cables ([1], [2]).

-

Ground and Earth’s System Installation: Grounding connection, welding ground stakes with high-quality standards ensuring long-term safety ([2], [4]).

-

Inspection, Testing, and Calibration: This includes electrical device testing, connection diagram checks to ensure compliance with technical criteria like voltage and current ([1], [2], [3]).

-

Commissioning, Trial Operations, and Handover: From internal inspections to energizing and observing stable operations before official handover ([1], [2], [3]).

This coordinated construction process, from survey to operation, ensures high efficiency and absolute safety of the electrical system through a professional workforce and strict adherence to standards.

The rigour in each step of constructing substations and electrical systems ensures stability and durability, enhancing the reliability of medium and low voltage electrical systems.

Electrical Equipment Maintenance

Alongside repairs, Quanganhcons offers electrical equipment maintenance services, ensuring prolonged efficiency for industrial electrical systems. The skilled technicians at Quanganhcons are dedicated to delivering reliable service through periodic power surveys and transformer oil testing.

Electrical equipment maintenance is crucial in construction and energy sectors, especially in Vietnam’s industrial environment. This technical routine involves several precise steps to ensure electrical systems operate safely and efficiently.

First, periodic equipment checks are basic yet critical. At this stage, technicians evaluate equipment condition to detect early failure signs such as current leakage, wear, cracks, rust, or component deformation. Thorough checks of wire connections, operating temperature, noise levels, and insulation help prevent issues.

Additionally, safely disconnecting power before maintenance is mandatory to ensure industrial electrical safety. Lockout or circuit breaker systems are common methods to protect personnel.

Next, cleaning electrical cabinets and surrounding equipment is essential to remove dust, grease, and rust. Tightening bolts, connections, and lubricating moving joints enhance equipment lifespan and efficiency.

Replacing damaged or deteriorated electrical parts is another crucial step for system stability. Equipped with optimal components, systems minimize production disruptions.

Periodic electrical testing and experiments ensure all systems function correctly. This involves measuring resistance, testing protection relays, and inspecting control units like ATS or capacitor controllers.

After completion, documenting and organizing reports is essential. These records aid in managing, monitoring maintenance effectiveness, and timely plan adjustments.

Finally, continuous employee training is key for updating skills and knowledge, enhancing electrical equipment maintenance quality.

Overall, regular electrical equipment maintenance not only extends equipment lifespan but also ensures worker safety, optimizing industrial electrical system performance.

Quanganhcons provides comprehensive solutions for technical and investment needs in repairing, constructing, and maintaining substations and industrial electrical systems. Committed to quality and reliability, each service enhances equipment efficiency and lifespan.

Contact Quanganhcons today for consultation and support: Hotline +84 9 1975 8191.

Quanganhcons offers repair, construction, and maintenance services for substations and medium to low voltage and industrial electrical systems, ensuring quality and reliable equipment sourcing.

[contact-form-7 id="7239967" title="Contact form 1"]

Related Posts

Tay Ninh Solar Power Planning: Technical Framework, Grid Interconnection, and Rollout Roadmap

Technical overview of solar planning in Tay Ninh: irradiation, grid capacity, permitting, design, operations, and [...]

Dec

Binh Duong Solar Planning: Regulatory Framework, Grid Interconnection, and an Implementation Roadmap for Factories and Industrial Parks

An overview of Binh Duong solar planning: legal framework, interconnection, design, risk management, and an [...]

Dec

Solar Farm Repair: O&M Workflow, IV Curve Diagnostics, Thermography, Inverter Service and Utility-Scale Safety

A utility-scale solar farm repair plan centered on O&M, IV curves, thermal imaging, inverter service, [...]

Dec

Dong Nai Solar Power Plan 2023–2025: Tri An 1,029 MW, Grid Upgrades and the DPPA Pathway

A complete look at Dong Nai’s solar power plan: Tri An 1,029 MW, irradiation potential, [...]

Nov

Quang Ngai Solar Power Plan 2024–2030: Legal Framework, Irradiance Potential, and Development Roadmap

A complete look at Quang Ngai’s solar power plan: capacity targets, irradiance (PVout), development zones, [...]

Nov

Solar Damage Assessment Services: On-Site Procedures, EL/IV/Thermography Testing & Compliance with Standards

Discover IEC/UL/NEC standard solar damage assessment processes: on-site evaluation, EL and IV curve testing, thermal [...]

Nov

Comprehensive Package Estimate for a 1800MVA 500kV Substation: Scope, Configuration 3x600MVA, Standards and Timeline Management

An overview of the 1800MVA 500kV substation estimate: construction scope, configuration 3x600MVA, GIS/AIS, SCADA, standards, [...]

Nov

Factory Electrical Systems: Comprehensive Design and Implementation Guide

Discover the detailed and safe process of factory electrical systems design and implementation. [...]

Oct

Blueprints Required for Factory Construction Permits

Discover the necessary blueprints in factory construction permit applications, from floor plans to electrical and [...]

Oct

What Are the Requirements for a Factory Construction Permit? A Comprehensive Guide

Explore the documentation and steps needed to secure a factory construction permit for streamlined project [...]

Oct

Factory Construction Permit Procedures in Vietnam: Essential Guidelines and Documents

Learn the procedures for securing a factory construction permit in Vietnam, focusing on document preparation [...]

Oct

Key Steps in the Factory Construction Process

Discover the essential steps and requirements for building factories. [...]

Oct

Comprehensive Electrical Substation Solutions by Quanganhcons

Discover the cutting-edge electrical substation solutions offered by Quanganhcons for industrial applications. [...]

Oct

Investment Costs for a 1MWp Solar Power System and Influencing Factors

Explore the investment costs for a 1MWp solar power system in Vietnam and the influencing [...]

Sep

QuangAnhcons: Elevating Wind Energy Solutions

Explore QuangAnhcons' leadership in wind energy and renewable solutions in Vietnam. [...]

Sep

Electrical Contractor Strategies at Becamex Industrial Park

Discover the strategic advancements and partnerships of the electrical contractor at Becamex Industrial Park. [...]

Sep

Investment Insights for 1MW Wind Energy in Vietnam: Costs and Opportunities

Discover the detailed analysis of costs and opportunities for investing in 1MW wind energy projects [...]

Sep

Advanced Electrical Installation Solutions by QuangAnhcons

Explore advanced electrical installation solutions and modern technology with QuangAnhcons. [...]

Sep

Enhancing Industrial Electrical Services with Quanganhcons

Discover Quanganhcons' expertise in industrial electrical services, offering efficient and sustainable power systems. [...]

Sep

Comprehensive MEP Solutions by QuangAnhcons: From Design to Maintenance Excellence

Discover optimal MEP solutions with QuangAnhcons, dedicated to excellence from design through maintenance. [...]

Sep