Revamping a factory’s electrical system is crucial to ensuring operational safety and efficiency. This involves stages like design, execution, installation, and safety verification.

Electrical System Upgrade Process

The process includes assessment, redesign, execution, and testing. Initially, evaluate current conditions and design an efficient system meeting safety standards. Installation involves main power cables post-transformer, dry transformers, generators, and conduit installation. Selecting appropriate conductors and load matching optimizes energy costs. Cable trays safeguard wiring, and final steps include grounding and thorough safety checks for stable operation.

- Assessment and Evaluation

- Conduct a detailed survey of all electrical components like switchboards, transformers, and conduits to ensure efficient upgrades.

- Determine current conditions and degradation levels to pinpoint required renovations.

- Planning and Redesign

- Modify or enhance systems for high efficiency and industrial safety compliance.

- Prepare detailed blueprints and cable specifications for selecting suitable equipment.

- Preparation for Execution

- Create a meticulous execution schedule, zoning to avoid production disruptions.

- Install uPVC conduits and prepare infrastructure for upgrading the electrical system.

- Implementation of Upgrades

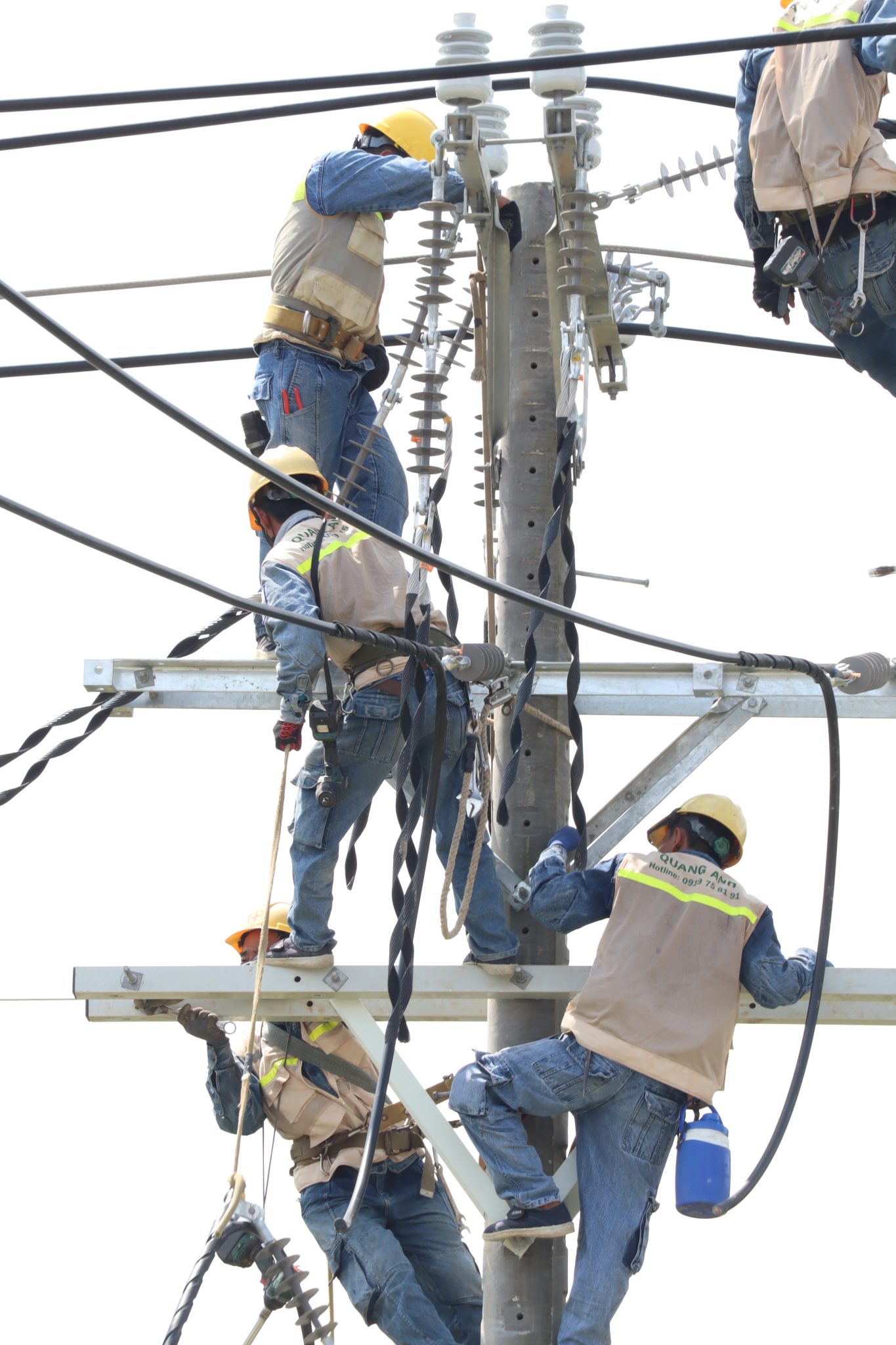

- Replace and install appropriate electrical appliances with proper technical connections.

- Ensure all executions adhere strictly to industrial safety standards.

- Post-Upgrade Testing and Maintenance

- Test system operation for detecting and correcting any faults.

- Schedule regular maintenance to retain optimal operational efficiency.

Critical Factors in Upgrade Process

- Work Safety: Rigorously follow safety protocols during upgrades, using protective gear for maximum safety.

- Zoning Strategy: Renovate by area without affecting factory operations.

- Technical Compliance: Follow industry standards for designing, executing, and maintaining systems.

- Documentation Management: Keep detailed records for future maintenance and repairs.

Key Considerations for Upgrades

Your factory’s electrical system renovation must carefully weigh safety, cost, and flexibility. Safety is paramount, achieved through strict adherence to design and installation standards. Devices like circuit breakers and fuses guard against fires and ensure system safety.

Choosing standard electrical equipment and materials is crucial for stability and safety. Effective load calculation and division guide apt conductor choices, preventing resource wastage and extending equipment life. Brands like ABB, Mitsubishi, Cadivi, or Schneider are potential considerations.

Energy efficiency improvements and cost reductions are long-term targets, achievable via energy-saving devices like LED systems and automation solutions. Installing a solar power system also aids sustainable and renewable energy use.

Conduct regular maintenance and repairs and prepare backup plans to ensure stable, effective system operation. Ultimately, economic feasibility and cost optimization are vital, ensuring investment yields lasting value for your enterprise.

Benefits of Electrical System Upgrades

Upgrading a factory’s electrical infrastructure yields numerous significant advantages. Primarily, it bolsters safety standards, minimizing electrical accident risks. An efficient system enhances production capacity and reduces long-term maintenance costs. Properly upgraded systems optimize power use, facilitate steady production, and adapt flexibly to future demands.

- Enhance Electrical Safety

Renovations address degraded components like cables and outlets, eliminating risks of fires or shocks to maximize electrical safety for users and assets. - Reduce Energy and Electricity Costs

Modern technology systems improve usage efficiency, cutting energy waste, thus conserving power, costs, and environmental impact. - Meet Modern Power Needs

Upgrades accommodate advanced devices, optimizing interaction with modern electrical systems and increasing flexibility and stability. - Improved Aesthetics and Orderliness

Reorganizing wiring systems enhances neatness and aesthetics, boosting spatial aesthetics in buildings or homes. - Extend System Lifespan and Efficiency

Replacing faulty components strengthens system durability, minimizes failures, and prolongs operational lifespan. - Support Clean, Eco-Friendly Power Usage

Upgrades facilitate clean energy integration with lithium-ion batteries and renewable energy, contributing to climate change mitigation. - Boost Operational Stability and Efficiency

Minimize technical malfunctions and unscheduled shutdowns, enhancing economic benefits for factories and businesses alike.

Upgrading the factory’s electrical systems not only boosts safety standards but also offers long-term investment returns. Enhanced systems boost productivity and adapt to expansion demands while cutting operating costs.

Contact QuangAnhcons now at +84 9 1975 8191 for detailed consultation and start revamping your factory’s electrical system.

QuangAnhcons offers factory electrical system renovation services, ensuring safe, efficient operations from design to full execution.

[contact-form-7 id="7239967" title="Contact form 1"]

Related Posts

Tay Ninh Solar Power Planning: Technical Framework, Grid Interconnection, and Rollout Roadmap

Technical overview of solar planning in Tay Ninh: irradiation, grid capacity, permitting, design, operations, and [...]

Dec

Binh Duong Solar Planning: Regulatory Framework, Grid Interconnection, and an Implementation Roadmap for Factories and Industrial Parks

An overview of Binh Duong solar planning: legal framework, interconnection, design, risk management, and an [...]

Dec

Solar Farm Repair: O&M Workflow, IV Curve Diagnostics, Thermography, Inverter Service and Utility-Scale Safety

A utility-scale solar farm repair plan centered on O&M, IV curves, thermal imaging, inverter service, [...]

Dec

Dong Nai Solar Power Plan 2023–2025: Tri An 1,029 MW, Grid Upgrades and the DPPA Pathway

A complete look at Dong Nai’s solar power plan: Tri An 1,029 MW, irradiation potential, [...]

Nov

Quang Ngai Solar Power Plan 2024–2030: Legal Framework, Irradiance Potential, and Development Roadmap

A complete look at Quang Ngai’s solar power plan: capacity targets, irradiance (PVout), development zones, [...]

Nov

Solar Damage Assessment Services: On-Site Procedures, EL/IV/Thermography Testing & Compliance with Standards

Discover IEC/UL/NEC standard solar damage assessment processes: on-site evaluation, EL and IV curve testing, thermal [...]

Nov

Comprehensive Package Estimate for a 1800MVA 500kV Substation: Scope, Configuration 3x600MVA, Standards and Timeline Management

An overview of the 1800MVA 500kV substation estimate: construction scope, configuration 3x600MVA, GIS/AIS, SCADA, standards, [...]

Nov

Factory Electrical Systems: Comprehensive Design and Implementation Guide

Discover the detailed and safe process of factory electrical systems design and implementation. [...]

Oct

Blueprints Required for Factory Construction Permits

Discover the necessary blueprints in factory construction permit applications, from floor plans to electrical and [...]

Oct

What Are the Requirements for a Factory Construction Permit? A Comprehensive Guide

Explore the documentation and steps needed to secure a factory construction permit for streamlined project [...]

Oct

Factory Construction Permit Procedures in Vietnam: Essential Guidelines and Documents

Learn the procedures for securing a factory construction permit in Vietnam, focusing on document preparation [...]

Oct

Key Steps in the Factory Construction Process

Discover the essential steps and requirements for building factories. [...]

Oct

Comprehensive Electrical Substation Solutions by Quanganhcons

Discover the cutting-edge electrical substation solutions offered by Quanganhcons for industrial applications. [...]

Oct

Investment Costs for a 1MWp Solar Power System and Influencing Factors

Explore the investment costs for a 1MWp solar power system in Vietnam and the influencing [...]

Sep

QuangAnhcons: Elevating Wind Energy Solutions

Explore QuangAnhcons' leadership in wind energy and renewable solutions in Vietnam. [...]

Sep

Electrical Contractor Strategies at Becamex Industrial Park

Discover the strategic advancements and partnerships of the electrical contractor at Becamex Industrial Park. [...]

Sep

Investment Insights for 1MW Wind Energy in Vietnam: Costs and Opportunities

Discover the detailed analysis of costs and opportunities for investing in 1MW wind energy projects [...]

Sep

Advanced Electrical Installation Solutions by QuangAnhcons

Explore advanced electrical installation solutions and modern technology with QuangAnhcons. [...]

Sep

Enhancing Industrial Electrical Services with Quanganhcons

Discover Quanganhcons' expertise in industrial electrical services, offering efficient and sustainable power systems. [...]

Sep

Comprehensive MEP Solutions by QuangAnhcons: From Design to Maintenance Excellence

Discover optimal MEP solutions with QuangAnhcons, dedicated to excellence from design through maintenance. [...]

Sep