- Planning and regulatory framework in Binh Duong

- Solar resource and climate conditions

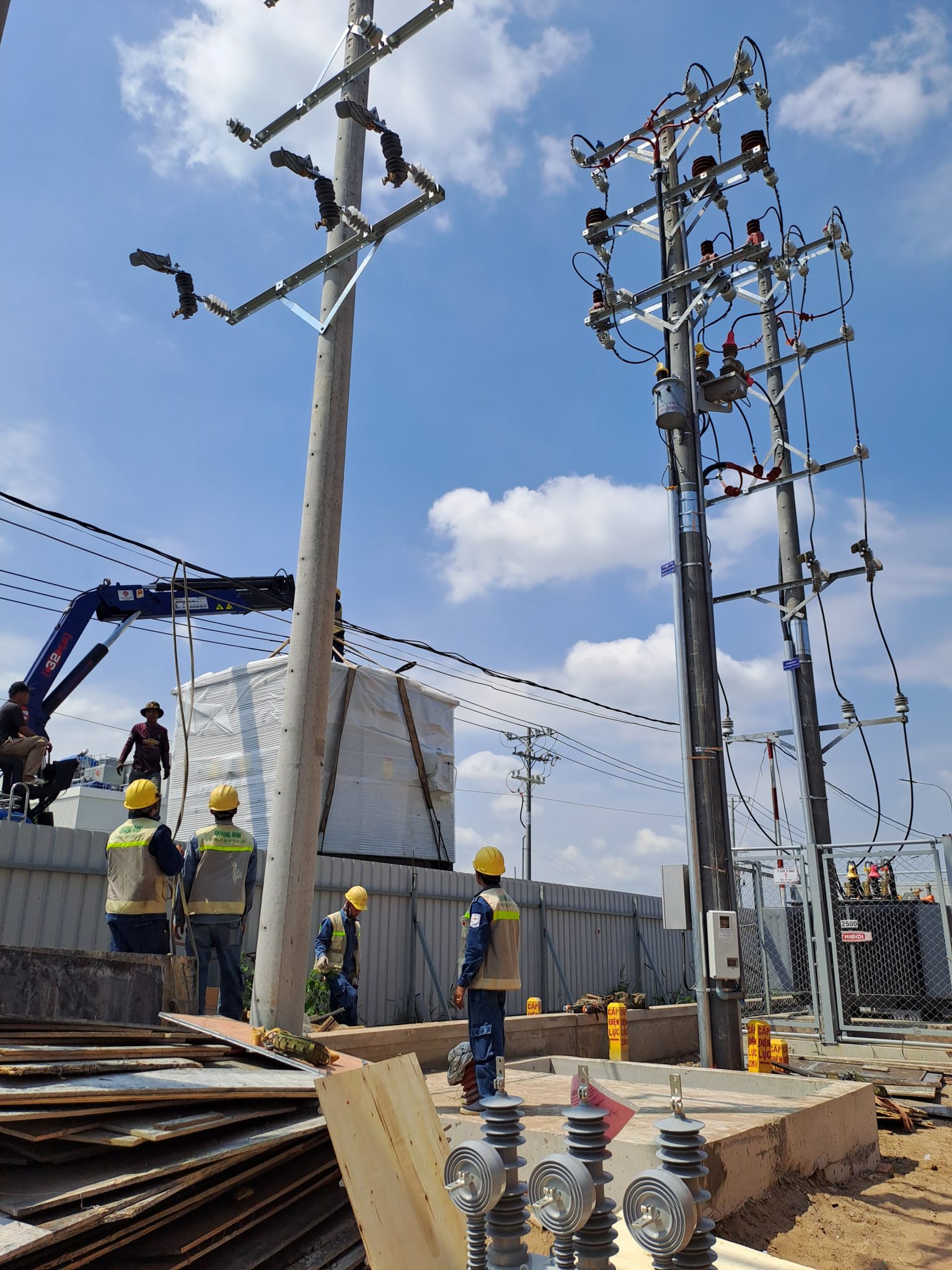

- Local grid and interconnection conditions

- Deployment models: self-consumption rooftop and suitable scenarios

- Procedures and technical compliance

- Technical design and performance modeling

- Operational risk management: grid, technical, and safety

- Operations, monitoring, and O&M for factories/industrial parks

Binh Duong is an industrial hub with high demand for reliable power and a clear transition toward clean energy. Solar planning here should align with national power planning, the provincial plan, and the actual hosting capacity of nearby networks, with priority given to factory and industrial-park rooftop systems for self-consumption. The core questions are interconnection feasibility, legal and technical documentation, and robust design that secures electrical safety and standard compliance across the project lifecycle. This guide consolidates the essentials: regulations, solar resource, grid infrastructure, deployment models, procedures, design and modeling, risk management, and operations.

Planning and regulatory framework in Binh Duong

In Binh Duong, solar projects must be consistent with national orientations and synchronized with provincial development plans. This ensures each project fits the local energy infrastructure without conflicts over grid capacity or site constraints. In the current context, rooftop photovoltaic systems for on-site consumption at factories and industrial parks are a practical approach, matching local objectives to maximize behind-the-meter use and ease interconnection pressures.

From a legal and technical standpoint, projects must comply with interconnection rules, electrical safety, fire protection, environmental requirements, and applicable TCVN/IEC standards. These requirements underpin safe, reliable operation and compatibility with the local grid.

- Planning review: Cross-check national and Binh Duong provincial plans before finalizing scale, location, and interconnection approach.

- Deployment model: Prioritize self-consumption rooftop systems for factories/industrial parks under current conditions.

- Interconnection: Follow current grid codes, coordinated protection, metering, and related technical conditions.

- Electrical safety and fire protection: Design, install, and operate to meet electrical safety and fire code requirements.

- Environment: Fulfill environmental obligations throughout the project lifecycle.

- Standards: Apply relevant TCVN/IEC standards for design, equipment, and testing.

Key risks if ignored include delayed or denied approvals, interconnection disruptions, electrical and fire-safety issues, and environmental non-compliance impacting operation and legal status.

To address common questions: planning in Binh Duong follows national and provincial guidance; self-consumption rooftops are a practical choice for now; and projects must meet interconnection, electrical safety, fire safety, environmental obligations, and relevant TCVN/IEC standards.

Solar resource and climate conditions

Binh Duong’s solar resource is suitable for PV, especially in the dry season when irradiance is relatively steady. Seasonal variability matters: production drops in the rainy season, so design and operations should anticipate this to secure annual energy targets.

How does the rainy season affect yield? Lower irradiance reduces PV output. Plan for seasonal operating strategies and load allocation, and set realistic month-by-month expectations to avoid unforeseen shortfalls.

For factory rooftops, temperature and industrial dust are two notable technical factors. High temperatures curb module conversion efficiency, so ventilation should be optimized to dissipate heat and maintain reasonable operating temperatures. Dust deposition on glass reduces effective irradiance and energy yield; a consistent cleaning plan aligned with site-specific soiling levels is essential.

- Optimize tilt: choose an angle that sheds water and limits dust retention, enabling better self-cleaning in rain.

- Optimize ventilation: ensure clear airflow beneath modules to reduce heat build-up on both roof and panels.

- Cleaning strategy: define cleaning procedures and monitor soiling losses to adjust frequency appropriately.

- Seasonal energy planning: reflect stable dry-season output and rainy-season dips in the energy assessment.

By integrating these factors from the design stage, PV rooftops in Binh Duong can sustain more stable output across seasons, matching industrial rooftop conditions and the local environment.

Local grid and interconnection conditions

Interconnection feasibility depends directly on the hosting capacity of the 22/110 kV network and nearby substations. For “What’s required to interconnect a rooftop system to the 22 kV grid in Binh Duong?”, the crux is to demonstrate that the 22 kV feeder can accommodate the project at the time of application and that documentation fully addresses system safety, anti-islanding protection, SCADA/monitoring, and curtailment plans when needed. Load flow and power quality assessments are mandatory to show grid impact.

Typical constraints during interconnection approval include: feeder/substation capacity limits; suitable protection and anti-islanding configuration; SCADA/monitoring integration per operating rules; curtailment commitments during overload or instability; and supporting simulations for load flow and power quality.

- Recommended dossier: load-flow analysis with operating scenarios; power-quality report; protection and anti-islanding design; SCADA/monitoring plan; and curtailment strategies by time/feeder condition.

- Risks if unmet: system safety issues, islanding risks, poor visibility for dispatch, and degraded power quality.

For “How to minimize grid impact at higher capacities?”, practical measures include: optimized protection and anti-islanding to isolate sources promptly; SCADA/monitoring for real-time visibility and coordination; flexible curtailment based on grid state; and using load-flow insights to select operating modes that unload sensitive elements. These steps support safe, controlled grid integration and readiness to meet utility requirements.

Deployment models: self-consumption rooftop and suitable scenarios

For factories in Binh Duong, self-consumption rooftop systems are advantageous where industrial loads run continuously. The benefit lies in aligning PV output with internal demand, prioritizing on-site use and easing stress on higher-voltage interconnections. This is well-suited to production lines that require stable daytime power, where the goal is to optimize internal consumption rather than rely on exporting to the grid.

By contrast, large ground-mounted projects should only be considered when clearly supported by planning guidance and local grid capability. This ensures interconnection, operations, and any expansions do not overload transmission infrastructure and remain consistent with local generation development.

Main constraints guiding the model choice include:

- Internal load: its continuity and coincidence with PV generation hours.

- Available space: suitability of existing areas for the chosen configuration.

- Operational needs: self-consumption priority, management approach, and internal optimization goals.

Reference scenarios:

- Self-consumption rooftop: appropriate where industrial loads are steady and the objective is to reduce pressure on higher-voltage interconnections.

- Large ground-mounted: consider only with clear planning orientation and proven grid capacity.

With this approach, factories can select an optimal model that meets operational goals and fits current grid and planning conditions.

Procedures and technical compliance

To deliver a compliant project in Binh Duong, coordinate regulatory procedures with end-to-end technical compliance. Focus on interconnection agreements with the utility, fire protection and environmental documentation per project scale, and completion of inspections and commissioning. All documents must align with design, applied standards, and safety measures.

- Interconnection agreement: work directly with the utility to align the interconnection solution. For “What documents are needed for interconnection approval in Binh Duong?”, the dossier should clearly reflect the agreed design, applicable standards, and related safety measures. Specific requirements are guided by the local utility during processing.

- Fire protection by scale: prepare fire protection documentation appropriate to the facility class. For “What are the checkpoints for inspection, commissioning, and fire protection?”, the sequence typically includes interconnection agreement, fire protection documentation by scale, and the required inspections and commissioning steps.

- Environment and occupational safety: for “What’s needed on environment and worker safety?”, prepare environmental documents by project scale; ensure occupational safety materials match the safety methods defined in the design.

- Inspection and commissioning: complete all required inspections and commissioning, ensuring technical records are consistent with the design and applicable standards.

At every stage, prioritize consistency between documentation, design, and safety measures to ensure smooth delivery and management compliance.

Technical design and performance modeling

Sound engineering starts with accurate simulations to define DC/AC configuration, manage electrical losses, and address rooftop thermal conditions. Emphasis should be on time-based irradiance and shading analysis, followed by inverter selection with control, protection, and SCADA integration capabilities, and finally module placement to limit shading and optimize cabling.

What needs to be modeled to optimize rooftop yield?

- Plane-of-array irradiance by season and hour to quantify energy potential.

- Shading from obstacles, row spacing, and tilt to limit performance losses.

- Rooftop thermal conditions affecting conversion efficiency and ventilation/clearance strategy.

- Electrical losses on DC/AC circuits, from routing to string configuration, to control voltage drop and balance loads.

How do DC/AC ratio and inverter selection matter?

- The DC/AC ratio sets the relationship between array size and inverter capacity, directly affecting overall efficiency and electrical losses.

- Choose inverters for robust control, protection features, and SCADA integration for centralized monitoring and safe, stable operation.

How to reduce shading and wiring losses on rooftops?

- Lay out modules to avoid dominant shade zones, optimize row spacing, and orient to match roof specifics.

- Optimize cable runs: shorten routes and harmonize string lengths to cut losses and maintain electrical balance.

- Account for thermal effects in layout: create ventilation gaps and avoid hot spots to preserve efficiency.

Common risks include persistent local shading, a mismatched DC/AC ratio that increases losses, and non-optimal cable routing. The remedy is to rely on irradiance/shading simulations, electrical and thermal assessments, and validated inverter selections with adequate control, protection, and SCADA.

Operational risk management: grid, technical, and safety

For factory rooftop operations, four priority risk groups are curtailment due to grid or low load, thermal derating, shading, and fire/electrical safety. Identifying them early and implementing lifecycle measures stabilizes output and protects assets.

- Curtailment (grid or low internal load): When the grid limits intake or internal load drops, output can be curtailed. Mitigate by optimizing power control to grid and load conditions, enabling flexible operation during high-risk windows.

- Thermal derating: Elevated temperatures reduce efficiency at certain times. Mitigate via appropriate mechanical layout to keep the system operating steadily across thermal conditions.

- Shading: Localized shading reduces output and introduces variability. Mitigate with appropriate mechanical layout to limit shading zones and avoid adverse interactions between blocks.

- Fire and electrical safety: Require early-stage protection and monitoring design to detect anomalies promptly, plus routine maintenance to keep the system in a safe state throughout operation.

In summary: key risks are curtailment, thermal issues, shading, and fire/electrical safety. Reduce curtailment by optimizing power control tied to grid and internal load. For safety, deploy early protection and monitoring and conduct regular maintenance to prevent and address anomalies.

Operations, monitoring, and O&M for factories/industrial parks

At factory or industrial-park scale, SCADA is the backbone of O&M: it captures real-time data, supervises equipment status, and triggers alarms. On top of that, track key KPIs such as performance ratio (PR), self-consumed energy, and availability. These metrics support performance evaluation, maintenance planning, and safety.

What’s needed for SCADA setup and operating KPIs? Define core measurement points (energy, soiling/thermal indicators, equipment status), time synchronization, alarm thresholds, and dashboards by shift/area. For KPIs: set PR targets based on design, monitor self-consumed energy to minimize internal losses, and maintain availability via redundancy and continuous monitoring.

Schedule cleaning and maintenance based on data rather than fixed intervals. Using soiling and thermal trends plus operating conditions, prioritize areas with abnormal PR drops, plan module cleaning, verify terminations/torque, and check for hot spots. Maintenance tasks should map to shift/weekly/monthly checklists driven by observed data. If neglected, risks include energy loss, prolonged downtime, and safety incidents—hence periodic inspections are essential to close gaps.

How to monitor performance and resolve faults? Use PR, self-consumption, and availability dashboards to spot deviations by time/component. When SCADA raises an alarm, categorize impact level, isolate the area, implement corrective actions, confirm recovery on KPIs, and record findings to refine maintenance schedules. This continuous loop stabilizes output and reduces operational risk.

Solar planning in Binh Duong should follow a clear sequence: planning alignment, interconnection assessment, technical modeling, documentation, implementation, and operational monitoring. Next steps for businesses include site surveys, reviewing grid hosting capacity, and initiating detailed simulations to define technical configuration and a working plan with the local utility.

Consult our engineering team to review interconnection feasibility and a suitable rollout roadmap for your factory or industrial park.

QuangAnhcons provides solar planning and delivery for factories/industrial parks: alignment with planning, interconnection assessment and documentation, site survey and TCVN/IEC-based design, energy and grid modeling (PVsyst/ETAP/DIgSILENT), construction and commissioning, SCADA/monitoring setup, and an O&M program.

[contact-form-7 id="7239967" title="Contact form 1"]

Related Posts

Tay Ninh Solar Power Planning: Technical Framework, Grid Interconnection, and Rollout Roadmap

Technical overview of solar planning in Tay Ninh: irradiation, grid capacity, permitting, design, operations, and [...]

Dec

Binh Duong Solar Planning: Regulatory Framework, Grid Interconnection, and an Implementation Roadmap for Factories and Industrial Parks

An overview of Binh Duong solar planning: legal framework, interconnection, design, risk management, and an [...]

Dec

Solar Farm Repair: O&M Workflow, IV Curve Diagnostics, Thermography, Inverter Service and Utility-Scale Safety

A utility-scale solar farm repair plan centered on O&M, IV curves, thermal imaging, inverter service, [...]

Dec

Dong Nai Solar Power Plan 2023–2025: Tri An 1,029 MW, Grid Upgrades and the DPPA Pathway

A complete look at Dong Nai’s solar power plan: Tri An 1,029 MW, irradiation potential, [...]

Nov

Quang Ngai Solar Power Plan 2024–2030: Legal Framework, Irradiance Potential, and Development Roadmap

A complete look at Quang Ngai’s solar power plan: capacity targets, irradiance (PVout), development zones, [...]

Nov

Solar Damage Assessment Services: On-Site Procedures, EL/IV/Thermography Testing & Compliance with Standards

Discover IEC/UL/NEC standard solar damage assessment processes: on-site evaluation, EL and IV curve testing, thermal [...]

Nov

Comprehensive Package Estimate for a 1800MVA 500kV Substation: Scope, Configuration 3x600MVA, Standards and Timeline Management

An overview of the 1800MVA 500kV substation estimate: construction scope, configuration 3x600MVA, GIS/AIS, SCADA, standards, [...]

Nov

Factory Electrical Systems: Comprehensive Design and Implementation Guide

Discover the detailed and safe process of factory electrical systems design and implementation. [...]

Oct

Blueprints Required for Factory Construction Permits

Discover the necessary blueprints in factory construction permit applications, from floor plans to electrical and [...]

Oct

What Are the Requirements for a Factory Construction Permit? A Comprehensive Guide

Explore the documentation and steps needed to secure a factory construction permit for streamlined project [...]

Oct

Factory Construction Permit Procedures in Vietnam: Essential Guidelines and Documents

Learn the procedures for securing a factory construction permit in Vietnam, focusing on document preparation [...]

Oct

Key Steps in the Factory Construction Process

Discover the essential steps and requirements for building factories. [...]

Oct

Comprehensive Electrical Substation Solutions by Quanganhcons

Discover the cutting-edge electrical substation solutions offered by Quanganhcons for industrial applications. [...]

Oct

Investment Costs for a 1MWp Solar Power System and Influencing Factors

Explore the investment costs for a 1MWp solar power system in Vietnam and the influencing [...]

Sep

QuangAnhcons: Elevating Wind Energy Solutions

Explore QuangAnhcons' leadership in wind energy and renewable solutions in Vietnam. [...]

Sep

Electrical Contractor Strategies at Becamex Industrial Park

Discover the strategic advancements and partnerships of the electrical contractor at Becamex Industrial Park. [...]

Sep

Investment Insights for 1MW Wind Energy in Vietnam: Costs and Opportunities

Discover the detailed analysis of costs and opportunities for investing in 1MW wind energy projects [...]

Sep

Advanced Electrical Installation Solutions by QuangAnhcons

Explore advanced electrical installation solutions and modern technology with QuangAnhcons. [...]

Sep

Enhancing Industrial Electrical Services with Quanganhcons

Discover Quanganhcons' expertise in industrial electrical services, offering efficient and sustainable power systems. [...]

Sep

Comprehensive MEP Solutions by QuangAnhcons: From Design to Maintenance Excellence

Discover optimal MEP solutions with QuangAnhcons, dedicated to excellence from design through maintenance. [...]

Sep