Article Table of Contents:

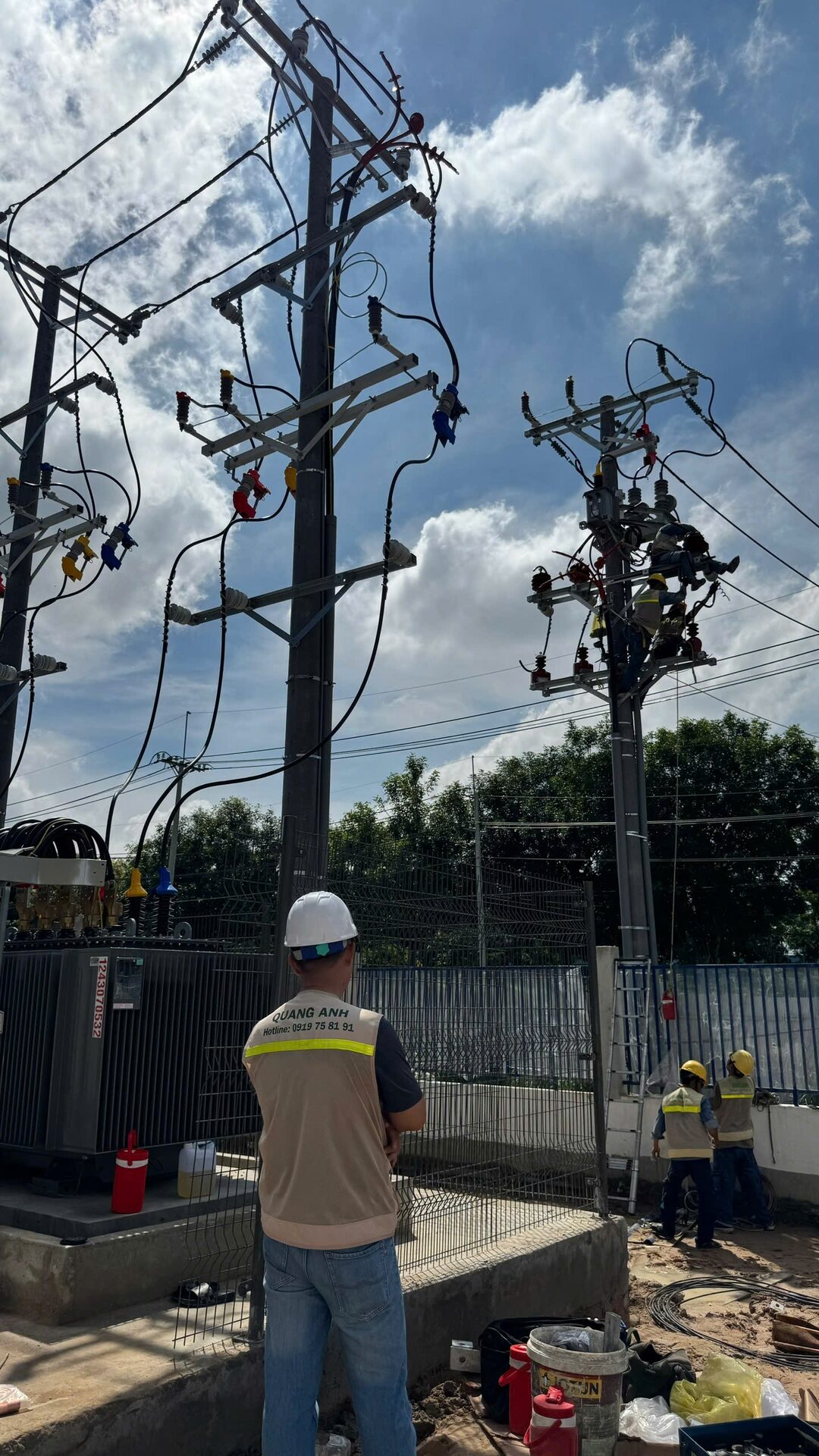

Quanganhcons is a professional contractor for designing and building 5000kVA substations, implementing advanced technology solutions and adhering to high technical standards.

Specifications of the 5000kVA Substation

The 5000kVA substation from Quanganhcons uses an oil transformer with a 5000kVA capacity, a voltage of 22/0.4kV, and core steel lamination technology. Technical features include a no-load current of 2%, a short circuit voltage of 4%, and a frequency of 50Hz, making it suitable for large industries requiring stable, efficient power.

The 5000kVA substation is crucial in providing stable power for industrial zones and large factories. Understanding technical specifications is vital to maximize efficiency.

Capacity and Technology

This substation has a rated capacity of 5000 kVA, using core steel lamination with copper or enamelled aluminum wire. Silicon steel cores minimize eddy currents due to superior magnetism. The standard operating frequency is 50 Hz.

Rated Voltage

Common high voltage ratings are 22kV or 35kV, and low voltage ratings are 0.4 kV or 6.6 kV. The typical connection group is Dyn11, ensuring reliability and power efficiency.

Energy Losses

- No-load loss (Po) ranges from 4980W to 11,000W depending on the transformer type.

- Short circuit loss (Pk) ranges from 39,500W to 53,000W.

- No-load current (Io) varies from 1.0% to 2.0%.

- Short circuit voltage (Uk) ranges from 4% to 7%.

Dimensions and Weight

For dry transformers, the standard size is about 2400mm (length) x 1800mm (width) x 2390mm (height). Copper winding weighs around 11,150 kg, while aluminum winding is approximately 10,000 kg.

Technical Standards, Testing, and Safety

International and Vietnamese standards applied include IEC 60076, IEC 60851, TCVN 6306. The standard frequency voltage test is 50/20 kV and impulse test voltage is 125/60 kV. Overload capacity is tested per IEC 60905 standards, ensuring safe and efficient operation.

Characteristics and Operational Care

Thin silicon steel cores reduce power loss, while coil design ensures electrical strength and high thermal resistance. Open-type transformers reduce noise and enhance durability. For storage, substations should be kept dry and protected from impact.

Recognizing these technical details aids management and engineers in making informed design and operational decisions for electrical systems.

Comprehensive Technical Solutions and Advantages of Quanganhcons

Quanganhcons develops substation designs to minimize energy loss, lower investment costs, and protect the environment. The company employs equipment from renowned brands like ABB and Schneider, enhancing operational efficiency, durability, and system safety.

Quanganhcons has distinguished itself in industrial electrical system design and construction with strict technical standards. Notably, the company excels in providing comprehensive solutions from design to routine maintenance, ensuring continuous and effective operations.

One major advantage is their seasoned and highly trained team. Quanganhcons engineers and technicians are not only well-trained but also experienced in fulfilling demanding technical and complex environment requirements to international standards, ensuring optimal performance of all industrial electrical systems implemented.

To enhance effectiveness and safety, Quanganhcons focuses on designing and executing low-voltage, medium-voltage, and substation systems with cost-effective solutions. The emphasis on safety and cost efficiency not only saves customers’ expenses but also improves production quality.

Modern technology is essential in Quanganhcons’ operations. The company actively adopts AI technology, digitalization, automation, and especially SCADA remote control systems. These solutions reduce downtime and optimize maintenance processes, ensuring stability for digital substations.

Quanganhcons’ underground electricity solutions and industry substation construction up to 35kV are also highly regarded, enhancing urban aesthetics while improving system safety and reliability.

A key highlight of Quanganhcons’ service is their ability to provide comprehensive M&E solutions, including both heavy and light electrical systems. By integrating automatic control and sensor solutions, the company not only optimizes performance but also significantly saves energy.

Regular maintenance is a crucial factor that Quanganhcons emphasizes to ensure systems operate efficiently and sustainably. These activities follow a specific plan and are part of the company’s renewable energy development strategy. Quanganhcons heavily invests in solar energy and quick electric vehicle charging services, aligning with the current green industry trend.

Prominent in technical solutions, Quanganhcons designs digital substations with intelligent SCADA control technology, reducing costs and enhancing reliability. Advanced design software like REVIT MEP and BIM ensures precision and efficiency in construction. Automation technology and sensors in electrical systems are crucial for maintaining efficiency and reducing energy consumption.

Construction Process and Maintenance Services

Quanganhcons implements strict processes for designing, constructing, and maintaining substations. The company emphasizes electrical safety standards and ensures that equipment has complete quality certifications. Quanganhcons provides comprehensive construction services, with substations types using certified materials with clear origins.

In the energy and construction fields, executing the Construction Process and Maintenance Services is essential for ensuring system performance and safety. From initial electrical installations, vital steps are strictly followed to ensure maximum sustainability and safety.

- Install protective pipes and electrical cables:

- Utilizing pipe types like trunking, ladder, or exposed pipes to safeguard cables and systematize electrical routing forms the initial stage of electrical installation. This facilitates efficient cable management and enhances safety levels.

- Pulling cables according to design diagrams:

- Accurately pulling cables per design to minimize unnecessary risks such as electrical short circuits. Connections are best established in plug boxes or lamp groove boxes for easier repairs.

- Installing electrical cabinets and control devices:

- According to design diagrams, electrical cabinets and control panels must be installed to not only meet technical criteria but also harmonize with the overall system.

- Connecting, testing, and system acceptance:

- Before handover, systems undergo stages of connecting, testing, and acceptance to detect and correct potential issues. Operational trials ensure systems meet technical standards and electrical safety regulations.

- Installing water pipe systems:

- Completing water supply and drainage systems in accordance with design drawings ensures proper slope for drainage and seal integrity to prevent leaks.

- Underground electrical procedures:

- For underground electricity, ensuring conduit stability by securing them with cement or concrete is vital. Note that conduit ends should be smoothed and joint spacing should adhere to technical standards to prevent damage upon construction completion.

- Adhering to safety rules during construction:

- Safety measures like careful concrete drilling, using expandable bolts when installing cable trays, and ensuring alignment of threaded rods are crucial to prevent structural load damage.

Beyond construction, the maintenance process is pivotal to ensuring the water and electrical systems operate efficiently:

- Periodic inspection: Evaluate the condition of electrical wires and devices, perform maintenance or replacement for damaged components.

- Regular cleaning and maintenance: Assists in stable system operation and prolongs equipment lifespan.

- Electrical safety inspection: Conducted per standards to ensure safety during usage.

Quanganhcons provides technical and investment solutions for 5000kVA substations, optimizing safety and performance for large enterprises. By integrating high-quality equipment with strict processes, companies can quickly leverage modern technology advantages in energy management.

Contact QuangAnhcons at Hotline: +84 9 1975 8191 to receive optimal 5000kVA substation solutions today.

QuangAnhcons is a reputable contractor offering design, construction, and maintenance services for substations, especially the 5000kVA variety. We ensure that equipment quality meets standards and the execution process is safe, saving costs for clients.

Related Posts

Dong Nai Solar Power Plan 2023–2025: Tri An 1,029 MW, Grid Upgrades and the DPPA Pathway

A complete look at Dong Nai’s solar power plan: Tri An 1,029 MW, irradiation potential, [...]

Nov

Quang Ngai Solar Power Plan 2024–2030: Legal Framework, Irradiance Potential, and Development Roadmap

A complete look at Quang Ngai’s solar power plan: capacity targets, irradiance (PVout), development zones, [...]

Nov

Solar Damage Assessment Services: On-Site Procedures, EL/IV/Thermography Testing & Compliance with Standards

Discover IEC/UL/NEC standard solar damage assessment processes: on-site evaluation, EL and IV curve testing, thermal [...]

Nov

Comprehensive Package Estimate for a 1800MVA 500kV Substation: Scope, Configuration 3x600MVA, Standards and Timeline Management

An overview of the 1800MVA 500kV substation estimate: construction scope, configuration 3x600MVA, GIS/AIS, SCADA, standards, [...]

Nov

Factory Electrical Systems: Comprehensive Design and Implementation Guide

Discover the detailed and safe process of factory electrical systems design and implementation. [...]

Oct

Blueprints Required for Factory Construction Permits

Discover the necessary blueprints in factory construction permit applications, from floor plans to electrical and [...]

Oct

What Are the Requirements for a Factory Construction Permit? A Comprehensive Guide

Explore the documentation and steps needed to secure a factory construction permit for streamlined project [...]

Oct

Factory Construction Permit Procedures in Vietnam: Essential Guidelines and Documents

Learn the procedures for securing a factory construction permit in Vietnam, focusing on document preparation [...]

Oct

Key Steps in the Factory Construction Process

Discover the essential steps and requirements for building factories. [...]

Oct

Comprehensive Electrical Substation Solutions by Quanganhcons

Discover the cutting-edge electrical substation solutions offered by Quanganhcons for industrial applications. [...]

Oct

Investment Costs for a 1MWp Solar Power System and Influencing Factors

Explore the investment costs for a 1MWp solar power system in Vietnam and the influencing [...]

Sep

QuangAnhcons: Elevating Wind Energy Solutions

Explore QuangAnhcons' leadership in wind energy and renewable solutions in Vietnam. [...]

Sep

Electrical Contractor Strategies at Becamex Industrial Park

Discover the strategic advancements and partnerships of the electrical contractor at Becamex Industrial Park. [...]

Sep

Investment Insights for 1MW Wind Energy in Vietnam: Costs and Opportunities

Discover the detailed analysis of costs and opportunities for investing in 1MW wind energy projects [...]

Sep

Advanced Electrical Installation Solutions by QuangAnhcons

Explore advanced electrical installation solutions and modern technology with QuangAnhcons. [...]

Sep

Enhancing Industrial Electrical Services with Quanganhcons

Discover Quanganhcons' expertise in industrial electrical services, offering efficient and sustainable power systems. [...]

Sep

Comprehensive MEP Solutions by QuangAnhcons: From Design to Maintenance Excellence

Discover optimal MEP solutions with QuangAnhcons, dedicated to excellence from design through maintenance. [...]

Sep

Comprehensive Electromechanical Contracting Solutions by QuangAnhcons

Explore QuangAnhcons' comprehensive services for efficient and safe energy system solutions. [...]

Sep

QuangAnhcons: Empowering Industrial Energy Solutions

Discover how QuangAnhcons delivers optimal industrial EPC solutions. [...]

Sep

Effective Industrial Construction Management and Execution

Optimize your industrial projects from design to execution with our contractor services. [...]

Sep