Enhancing industrial electrical systems ensures meeting load demands, optimizing efficiency, and maintaining safety, addressing the increasing production needs.

Importance of Upgrading Industrial Electrical Systems

Upgrading industrial electrical systems is essential to accommodate increased equipment and production capacities while minimizing risks such as outdated wiring leading to potential fires and inefficiencies.

It is not just an optimal choice but a necessary requirement for safe and efficient plant operations.

- Ensure Safety and Reduce Risks: Replacing outdated equipment, enhancing insulation, and installing advanced protection systems like smart relays helps prevent hazards like fires and electrical shocks.

- Boost Performance and Energy Savings: Adoption of new technologies like next-generation inverters and industrial LEDs results in more efficient systems. Additionally, automated energy management systems optimize energy usage, reducing operational costs.

- Meet Expanded Production Requirements: Technological advancements such as IoT and industrial robots demand higher power capacity, necessitating upgrades to maintain stable power supply.

- Comply with New Standards: Adhering to electrical safety and environmental standards like IEC and ISO 50001 ensures legal compliance, preventing unnecessary legal risks.

- Facilitate Digital Transformation and Automation: Systems like SCADA and real-time monitoring serve as the foundation for modern digital plants, allowing seamless integration of IoT sensors and data analysis.

- Minimize Downtime: Modern electrical systems can reduce downtime by 30-50% owing to their stability and reliability.

- Environmental Protection: Newer technologies not only conserve energy but also cut CO₂ emissions, aligning with global sustainable development trends.

Highlighted Upgrade Trends (2023-2025)

- Smart Lighting Systems: Automatically adjust brightness according to production needs, optimizing light resources.

- GIS Substations: Reduce installation space by up to 40% compared to traditional stations, optimizing factory space.

- Surge Protection Systems: Safeguard sensitive equipment, ensuring safety in industrial environments.

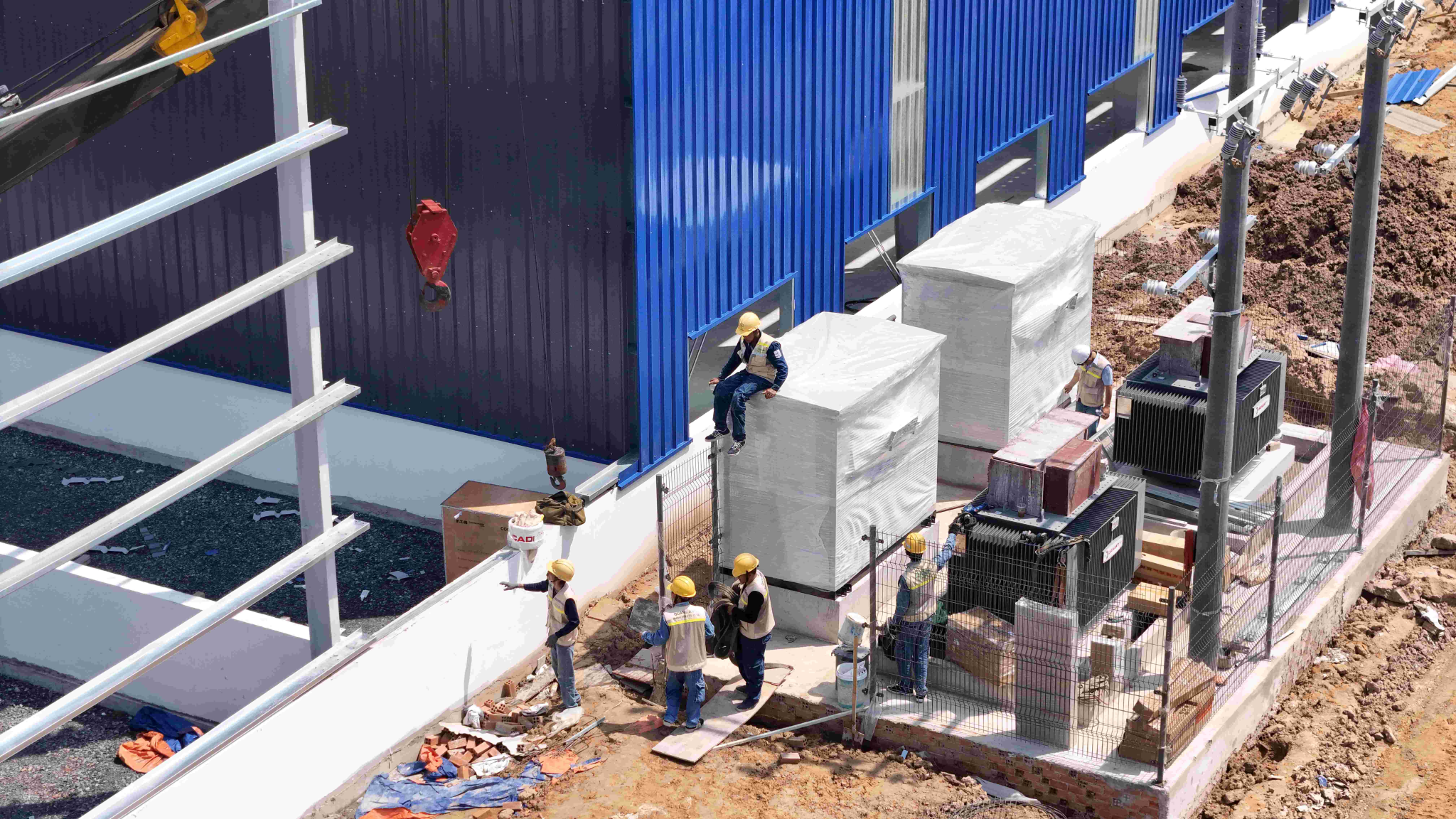

Technical Process for Upgrading Industrial Electrical Systems

The upgrade process involves assessing the current situation, designing high and low voltage networks, and implementing upgrades. Replacing conductors and equipment to meet IEC/TCVN standards and installing energy monitoring systems like SCADA, IoT is necessary for load management.

Amid industrial modernization, upgrading industrial electrical systems is crucial to meet the growing electrical load demand. This article details the electrical construction process, applying the latest electrical IEC standards and monitoring systems.

- Construction and Upgrade Process

- Survey and Design: Begin with a detailed assessment of existing electrical systems and determining new load requirements. Detailed design drawings must consider elements like cable distance, electrical cabinet layout, and load distribution adhering to current technical standards.

- Material Preparation: Carefully select equipment like transformers from reputable brands such as ABB, Mitsubishi, Schneider, and essential materials like Cadivi cables meeting IEC and TCVN quality standards.

- Installation Implementation: Includes medium voltage cable laying, electrical cabinet installation, circuit breakers, and industrial lighting systems. This process requires strict adherence to technical and safety requirements to ensure maximum effectiveness and safety.

- Testing and Trial Operation

- Operational Testing: Conduct detailed checks on actual power capacity and voltage stability post-upgrade. Load capacity and potential problems need close monitoring through IoT-based remote monitoring systems.

- Safety Evaluation: Ensure electrical leakage, grounding, and insulation comply with TCVN 5699-1:2010 standards for operational safety.

- Post-Upgrade Maintenance and Optimization

- Regular Maintenance: The maintenance process should include device status monitoring and frequent measurement of electrical parameters such as insulation resistance and leakage current to detect issues early.

- System Optimization: Employ energy-saving solutions like industrial LED lights and variable speed drives to enhance energy efficiency.

- Applied Technical Standards

- International Standards: Apply IEC standards such as IEC 61000-4-2 for interference immunity and IEC 61439 for electrical cabinets to ensure quality and safety.

- Vietnamese Standards: National standards like TCVN 8241-4-2 and TCVN 1983:2013 are widely applied in the installation and maintenance of electrical systems to ensure maximum safety.

- New Technologies in Industrial Electrical Upgrades

- Remote Monitoring Systems: IoT becomes a powerful tool in monitoring operational parameters like temperature, load current, and resource coordination. This supports failure prediction and maintenance optimization.

- Advanced Insulating Materials: The use of LSZH cables exemplifies reduced fire hazards and enhanced environmental safety.

The upgrade process demands close coordination from design, execution to operational monitoring, always adhering to standards and new technologies for optimal outcomes.

Technology Trends in Upgrading Industrial Electrical Systems

Advancements include smart electrical system integration with IoT sensors, using renewable energy solutions like rooftop solar, and employing premium insulating materials like XLPE, CSR to optimize electrical systems.

Today, the importance of upgrading industrial electrical systems is undeniable, crucial for sustainable development. In the face of advancing technology, integrating IoT solutions and smart electrical systems revolutionizes these upgrades.

Advanced AI has evolved to perform the role of Agentic AI, making autonomous decisions and optimizing electrical system operations without manual intervention. This not only effectively manages electrical loads but also helps with demand forecasting and rapid fault detection. AI plays a crucial role in analyzing large datasets from IoT sensors, aiding businesses in energy-saving strategies and reducing operational costs.

Moreover, smart IoT sensors have been widely implemented for monitoring device performance, environmental factors like temperature and humidity, and real-time electricity consumption. Alongside the development of 5G connectivity, data from millions of devices can be transmitted quickly and efficiently, laying the groundwork for highly automated industrial electrical systems. This is truly a major boost for the trend towards smart electrical systems.

Additionally, the need for clean and energy-efficient technologies is gaining focus. The management of refrigerants has shifted towards environmentally friendly options like CO2, ammonia, and propane, replacing HCFC and HFC to reduce greenhouse gas emissions. Inverter technology also demonstrates its efficiency by allowing flexible power adjustments, reducing energy consumption by 30-50% compared to traditional systems.

Automation is becoming more robust with integrated control systems combined with IoT and AI technology, automating production processes, reducing errors, and increasing accuracy. Predictive maintenance is widely applied, using AI to analyze equipment data to forecast failures and plan proactive maintenance.

Furthermore, to ensure energy security and fluctuation management, the development of energy storage systems such as industrial batteries and thermal storage technology is being actively promoted. Microgrid, an innovative solution, combined with renewable energy, helps continuously supply power to industrial zones.

In Vietnam, with commitments to green transformation, international standards like ISO 50001 are being applied to energy management and reducing carbon emissions in industrial operations. Heat recovery technology is being fully exploited to utilize waste heat for electricity generation or heating, enhancing overall efficiency.

Upgrading industrial electrical systems offers numerous benefits in technology and investment, enhancing performance and responsiveness, contributing to sustainable industry development.

Contact QuangAnhcons via Hotline: +84 9 1975 8191 for optimizing your industrial electrical systems.

QuangAnhcons specializes in consulting and implementing industrial electrical system upgrades, ensuring international standards and high effectiveness.

[contact-form-7 id="7239967" title="Contact form 1"]

Related Posts

Tay Ninh Solar Power Planning: Technical Framework, Grid Interconnection, and Rollout Roadmap

Technical overview of solar planning in Tay Ninh: irradiation, grid capacity, permitting, design, operations, and [...]

Dec

Binh Duong Solar Planning: Regulatory Framework, Grid Interconnection, and an Implementation Roadmap for Factories and Industrial Parks

An overview of Binh Duong solar planning: legal framework, interconnection, design, risk management, and an [...]

Dec

Solar Farm Repair: O&M Workflow, IV Curve Diagnostics, Thermography, Inverter Service and Utility-Scale Safety

A utility-scale solar farm repair plan centered on O&M, IV curves, thermal imaging, inverter service, [...]

Dec

Dong Nai Solar Power Plan 2023–2025: Tri An 1,029 MW, Grid Upgrades and the DPPA Pathway

A complete look at Dong Nai’s solar power plan: Tri An 1,029 MW, irradiation potential, [...]

Nov

Quang Ngai Solar Power Plan 2024–2030: Legal Framework, Irradiance Potential, and Development Roadmap

A complete look at Quang Ngai’s solar power plan: capacity targets, irradiance (PVout), development zones, [...]

Nov

Solar Damage Assessment Services: On-Site Procedures, EL/IV/Thermography Testing & Compliance with Standards

Discover IEC/UL/NEC standard solar damage assessment processes: on-site evaluation, EL and IV curve testing, thermal [...]

Nov

Comprehensive Package Estimate for a 1800MVA 500kV Substation: Scope, Configuration 3x600MVA, Standards and Timeline Management

An overview of the 1800MVA 500kV substation estimate: construction scope, configuration 3x600MVA, GIS/AIS, SCADA, standards, [...]

Nov

Factory Electrical Systems: Comprehensive Design and Implementation Guide

Discover the detailed and safe process of factory electrical systems design and implementation. [...]

Oct

Blueprints Required for Factory Construction Permits

Discover the necessary blueprints in factory construction permit applications, from floor plans to electrical and [...]

Oct

What Are the Requirements for a Factory Construction Permit? A Comprehensive Guide

Explore the documentation and steps needed to secure a factory construction permit for streamlined project [...]

Oct

Factory Construction Permit Procedures in Vietnam: Essential Guidelines and Documents

Learn the procedures for securing a factory construction permit in Vietnam, focusing on document preparation [...]

Oct

Key Steps in the Factory Construction Process

Discover the essential steps and requirements for building factories. [...]

Oct

Comprehensive Electrical Substation Solutions by Quanganhcons

Discover the cutting-edge electrical substation solutions offered by Quanganhcons for industrial applications. [...]

Oct

Investment Costs for a 1MWp Solar Power System and Influencing Factors

Explore the investment costs for a 1MWp solar power system in Vietnam and the influencing [...]

Sep

QuangAnhcons: Elevating Wind Energy Solutions

Explore QuangAnhcons' leadership in wind energy and renewable solutions in Vietnam. [...]

Sep

Electrical Contractor Strategies at Becamex Industrial Park

Discover the strategic advancements and partnerships of the electrical contractor at Becamex Industrial Park. [...]

Sep

Investment Insights for 1MW Wind Energy in Vietnam: Costs and Opportunities

Discover the detailed analysis of costs and opportunities for investing in 1MW wind energy projects [...]

Sep

Advanced Electrical Installation Solutions by QuangAnhcons

Explore advanced electrical installation solutions and modern technology with QuangAnhcons. [...]

Sep

Enhancing Industrial Electrical Services with Quanganhcons

Discover Quanganhcons' expertise in industrial electrical services, offering efficient and sustainable power systems. [...]

Sep

Comprehensive MEP Solutions by QuangAnhcons: From Design to Maintenance Excellence

Discover optimal MEP solutions with QuangAnhcons, dedicated to excellence from design through maintenance. [...]

Sep