Our transformer repair services include inspections, cleaning, minor repairs, and overall restoration to ensure safe, stable, and efficient operations.

Process of Transformer Repair and Maintenance

Our repair services follow a stringent process ensuring machinery operates efficiently. Initially, electrical safety is prioritized by adhering to fire safety regulations to prevent accidents. This is followed by external cleaning of transformers, involving cleaning, repainting, and welding damaged areas. Next is the inspection and repair of components like gaskets, valves, and protective parts. Internal maintenance involves cleaning, oil changes, and cooling system checks. Final testing and functionality assessments are conducted before returning the transformer to service.

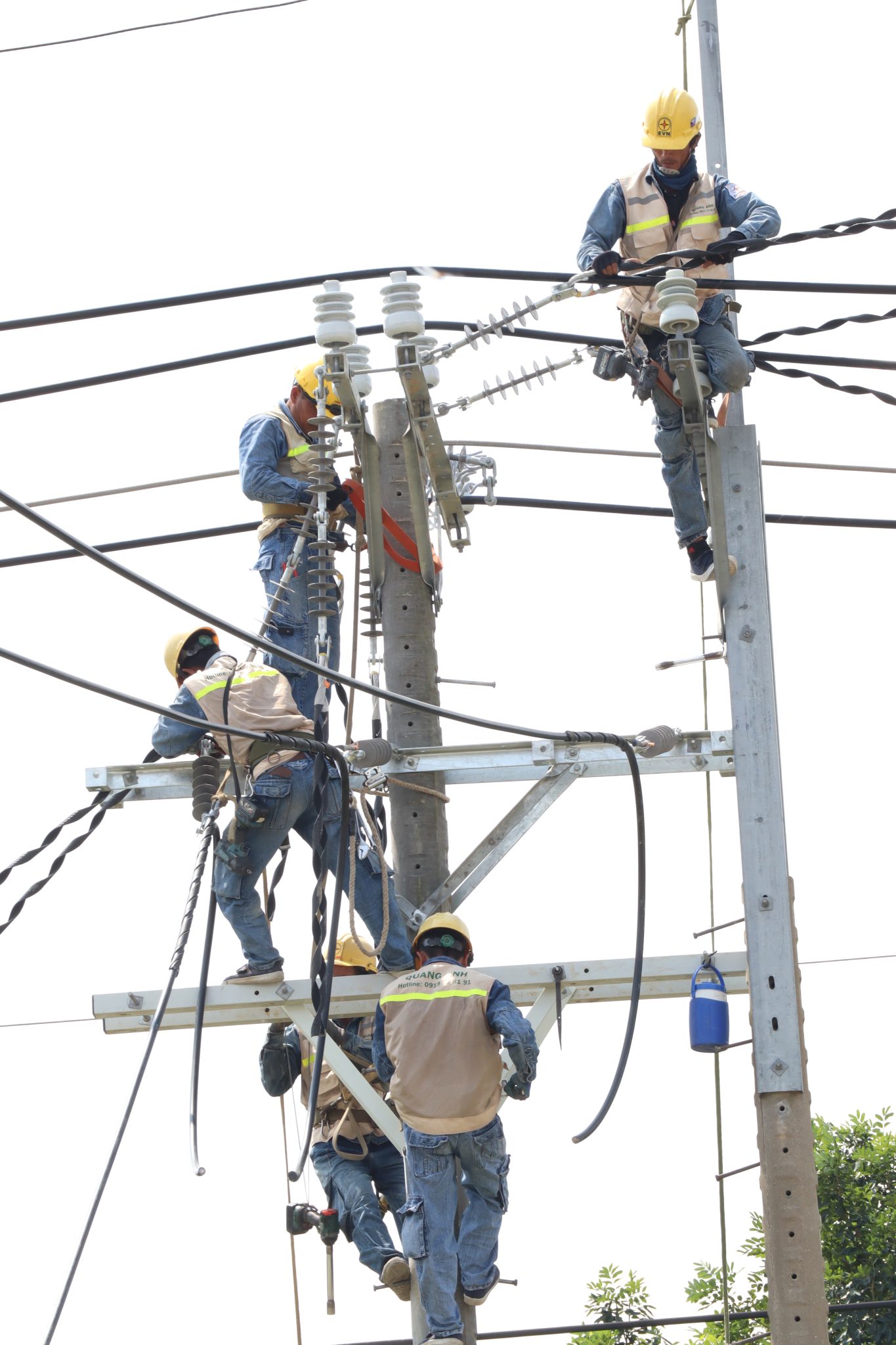

In Vietnam’s electrical engineering sector, the repair and maintenance process of transformers is vital for maintaining electrical system efficiency and safety. Emphasis should first be placed on transformer safety. Strict adherence to electrical and safety protocols is mandatory, alongside compliance with fire regulations before repair work begins.

The transformer cleaning process includes dusting external parts, cleaning ceramic surfaces, repainting, and repairing radiators when necessary. Engineers conduct inspections and adjustments to promptly identify any misalignments or faults in critical components.

Replacing parts involves upgrading transformers’ internal components such as gaskets, valves, and other protective elements, which must be done meticulously to ensure stable operation.

After completing these steps, testing and restarting operations are essential to confirm the transformer’s readiness for safe use.

Regarding maintenance, particularly for oil-filled transformers, a regular maintenance schedule is applied to monitor and analyze device performance comprehensively. Transformer maintenance involves complete cleaning of stations, oil sampling and testing, and topping up oil if necessary. Tightening cable connections and joints is also crucial for maintaining operational safety and efficiency.

Regular checks on cable insulation and oil temperature help in early detection of potential issues. Providing advice and strengthening transformer substation foundations also play a significant role in ensuring stable and sustainable electrical system operations.

For dry transformers, the focus is on inspecting the core, cables, cleaning the core and cooling fans, tightening wire connections, and monitoring operating temperatures. Annual repair and maintenance reduce fire risks and maintain stable electrical system operations.

Levels of Transformer Repair

Transformer repair services are categorized into three levels. Minor repairs focus on exterior cleaning and minor fault checking without oil removal. Regular maintenance involves removing the transformer’s core for comprehensive inspection and repair, often including insulation drying. Extensive overhauls involve rewinding coils, repairing cores, and restoring insulation to prolong the device’s lifespan.

Transformers are crucial in maintaining electrical system stability, with repair levels defined by intervention depth and workload.

- Minor Transformer Repair: Light repairs focusing on external checks and cleaning without oil or component removal. Minor damages like loose connections or slight corrosion are fixed on site.

- Regular Overhaul: By removing the transformer’s core from its casing, regular overhauls allow thorough inspection and repair. This includes drying insulation and replacing insulating oil when necessary for long-term efficiency.

- Extensive Overhaul: This is the most intensive repair level, involving complete rewinding of coils, repairing and restoring transformer cores, and replacing heavily damaged components.

The transformer repair process consists of basic steps:

- Safety Measures: Ensuring electrical and labor safety, and necessary fire prevention protocols.

- External Cleaning: Cleaning the transformer before conducting inspections and repairs.

- Inspection and Adjustment: Performing checks on external components, assessing insulating oil condition, protective devices, and connection fittings.

- Replacement, Upgrade of Equipment: Replacing damaged components, rewinding coils, repairing cores, and replacing insulating oil as needed.

- Testing and Energizing: After repairs, testing ensures safety and efficiency before returning the transformer to operation.

Maintenance also includes tasks like changing insulating oil, repairing damaged welds, checking and replacing faulty seals, and conducting comprehensive transformer condition surveys to detect and address any issues promptly.

Significance of Regular Maintenance for Transformers

Regular maintenance on transformers, conducted every 3 to 6 months, involves proactive checks and repairs, extending lifespan and reducing severe damage risks. This process includes cooling system evaluations, oil changes, and identifying part conditions for timely management. This is a crucial aspect of transformer repair services, ensuring safe and reliable machinery operation.

Routine maintenance is vital in the electrical system, sustaining stability, durability, and safety of the grid. Detecting early signs of issues like phase imbalance, component failure, or oil quality degradation prevents significant faults, preserving grid safety.

Regular checks not only safeguard the system but also protect operators and communities from explosion risks. Transformers are integral to the power grid, and even minor issues can disrupt production and daily life, causing economic losses.

Sustained maintenance also extends equipment life by cleaning, inspecting, and replacing worn parts, ensuring stable operation and reducing major breakdown risks. This also saves substantial costs on replacements or repairs.

Typically, regular electrical inspections are conducted every 3–6 months, while comprehensive maintenance should occur annually or per manufacturer or utility specifications. Key maintenance tasks include full transformer cleaning, temperature and oil level checks, insulation assessments, bolt tightening, and control unit performance evaluations.

Overall, regular transformer maintenance is crucial, not only for ensuring safe grid operation but also for protecting business investments.

Implementing proper transformer repair services not only maintains stable operation but also extends equipment lifespan, ensuring operational safety. With professional procedures from inspection, cleaning to maintenance and functionality testing, transformers continue to play a critical role in your power system.

Contact QuangAnhcons for free consultation and explore professional transformer repair services via our Hotline: +84 9 1975 8191.

QuangAnhcons offers professional transformer repair services, ensuring electrical safety, cleaning, inspection, and comprehensive restoration. Our team is committed to enhancing equipment lifespan and ensuring stable, safe energy system operations.

[contact-form-7 id="7239967" title="Contact form 1"]

Related Posts

Tay Ninh Solar Power Planning: Technical Framework, Grid Interconnection, and Rollout Roadmap

Technical overview of solar planning in Tay Ninh: irradiation, grid capacity, permitting, design, operations, and [...]

Dec

Binh Duong Solar Planning: Regulatory Framework, Grid Interconnection, and an Implementation Roadmap for Factories and Industrial Parks

An overview of Binh Duong solar planning: legal framework, interconnection, design, risk management, and an [...]

Dec

Solar Farm Repair: O&M Workflow, IV Curve Diagnostics, Thermography, Inverter Service and Utility-Scale Safety

A utility-scale solar farm repair plan centered on O&M, IV curves, thermal imaging, inverter service, [...]

Dec

Dong Nai Solar Power Plan 2023–2025: Tri An 1,029 MW, Grid Upgrades and the DPPA Pathway

A complete look at Dong Nai’s solar power plan: Tri An 1,029 MW, irradiation potential, [...]

Nov

Quang Ngai Solar Power Plan 2024–2030: Legal Framework, Irradiance Potential, and Development Roadmap

A complete look at Quang Ngai’s solar power plan: capacity targets, irradiance (PVout), development zones, [...]

Nov

Solar Damage Assessment Services: On-Site Procedures, EL/IV/Thermography Testing & Compliance with Standards

Discover IEC/UL/NEC standard solar damage assessment processes: on-site evaluation, EL and IV curve testing, thermal [...]

Nov

Comprehensive Package Estimate for a 1800MVA 500kV Substation: Scope, Configuration 3x600MVA, Standards and Timeline Management

An overview of the 1800MVA 500kV substation estimate: construction scope, configuration 3x600MVA, GIS/AIS, SCADA, standards, [...]

Nov

Factory Electrical Systems: Comprehensive Design and Implementation Guide

Discover the detailed and safe process of factory electrical systems design and implementation. [...]

Oct

Blueprints Required for Factory Construction Permits

Discover the necessary blueprints in factory construction permit applications, from floor plans to electrical and [...]

Oct

What Are the Requirements for a Factory Construction Permit? A Comprehensive Guide

Explore the documentation and steps needed to secure a factory construction permit for streamlined project [...]

Oct

Factory Construction Permit Procedures in Vietnam: Essential Guidelines and Documents

Learn the procedures for securing a factory construction permit in Vietnam, focusing on document preparation [...]

Oct

Key Steps in the Factory Construction Process

Discover the essential steps and requirements for building factories. [...]

Oct

Comprehensive Electrical Substation Solutions by Quanganhcons

Discover the cutting-edge electrical substation solutions offered by Quanganhcons for industrial applications. [...]

Oct

Investment Costs for a 1MWp Solar Power System and Influencing Factors

Explore the investment costs for a 1MWp solar power system in Vietnam and the influencing [...]

Sep

QuangAnhcons: Elevating Wind Energy Solutions

Explore QuangAnhcons' leadership in wind energy and renewable solutions in Vietnam. [...]

Sep

Electrical Contractor Strategies at Becamex Industrial Park

Discover the strategic advancements and partnerships of the electrical contractor at Becamex Industrial Park. [...]

Sep

Investment Insights for 1MW Wind Energy in Vietnam: Costs and Opportunities

Discover the detailed analysis of costs and opportunities for investing in 1MW wind energy projects [...]

Sep

Advanced Electrical Installation Solutions by QuangAnhcons

Explore advanced electrical installation solutions and modern technology with QuangAnhcons. [...]

Sep

Enhancing Industrial Electrical Services with Quanganhcons

Discover Quanganhcons' expertise in industrial electrical services, offering efficient and sustainable power systems. [...]

Sep

Comprehensive MEP Solutions by QuangAnhcons: From Design to Maintenance Excellence

Discover optimal MEP solutions with QuangAnhcons, dedicated to excellence from design through maintenance. [...]

Sep