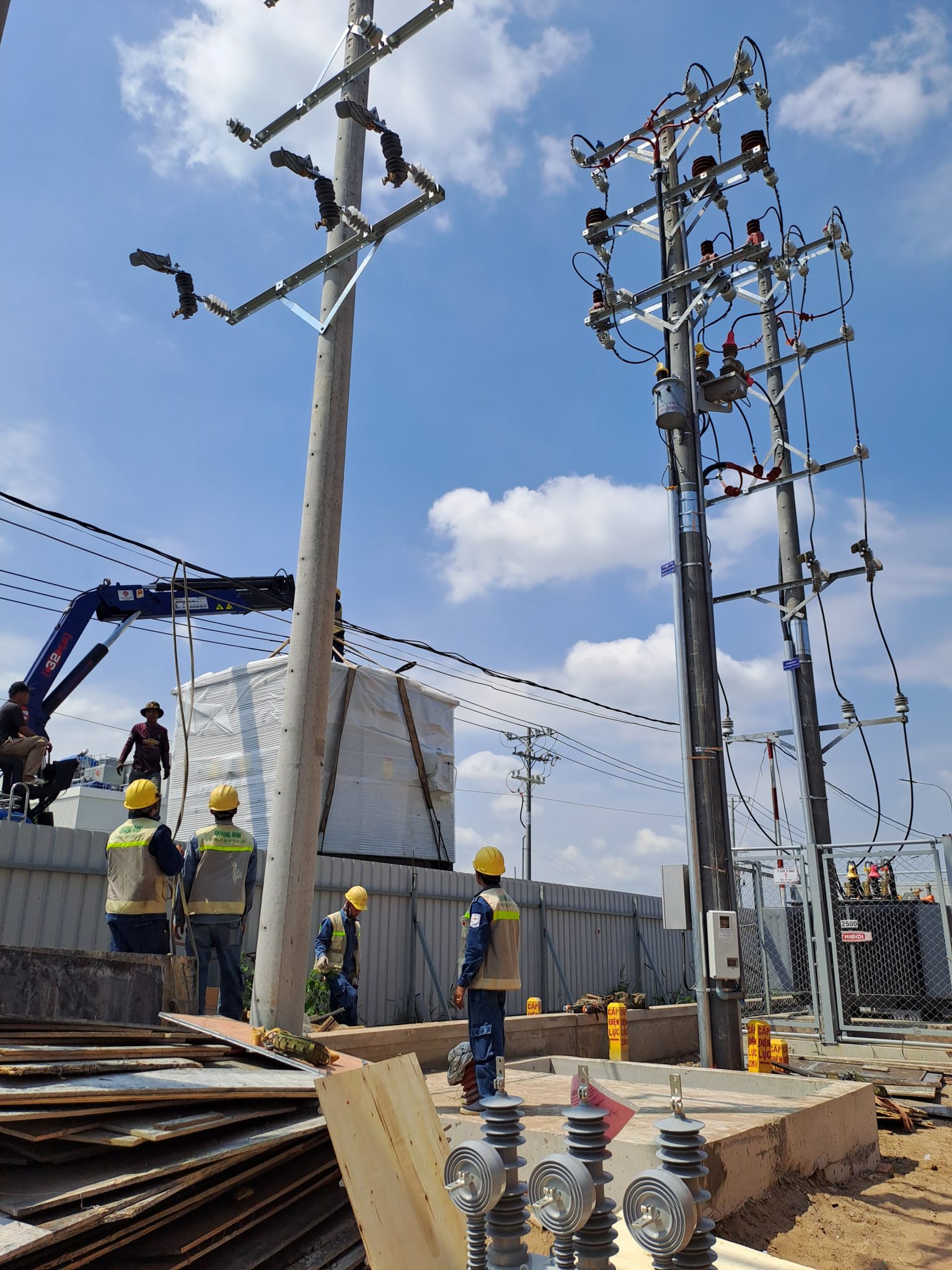

Maintaining industrial electrical systems is crucial for ensuring the continuous, safe, and efficient operation of production equipment.

Detailed Electrical Maintenance Process

The process involves periodic checks of the overall system status to detect any signs of faults or failures. Measuring voltage and current for each phase in the switchboard and comparing with previous records is vital. Cleaning and servicing by removing dust and grease buildup ensures smooth operation and prevents short circuits. Replacing faulty parts and adjusting equipment to operate correctly is essential. Ensuring electrical safety standards are met is imperative for all equipment. Thorough documentation and reporting of maintenance activities, inspection results, and problem resolutions is the final, critical step.

-

Preparation and Load Isolation

- Disconnect power as needed to ensure maintenance personnel safety. This includes detaching loads from generators and isolating switchboard mains.

- Prepare all required tools and equipment.

-

Operational Data Documentation

- Record operational logs provided by the client.

- Document input and output voltage values of the system.

-

Maintenance Execution

- Regular Inspections: Check the overall condition of the electrical system to identify signs of faults, failures, current leakage, and wear.

- Equipment Cleaning: Remove dust and grease buildup from electrical equipment to ensure system safety.

- Servicing and Component Replacement: Service parts to ensure smooth operation and replace defective components.

-

Safety Check

- Ensure that all equipment and systems comply with safety standards.

- Conduct necessary tests to confirm electrical system safety.

-

System Testing and Verification

- After completing maintenance, perform tests to ensure stable and efficient operation of the system.

-

Results Reporting

- Prepare a detailed report on maintenance results, including identified issues and actions taken. This is a critical step in the maintenance reporting process.

- Propose improvements for the next maintenance cycle.

-

Training and Improvement

- Ensure maintenance staff are fully trained in technical and safety aspects.

- Maintain continuous skill updates for staff.

During routine maintenance, technicians should strictly adhere to safety regulations and use personal protective equipment to ensure both personnel and system safety. This detailed maintenance process not only enhances system performance but also prevents unexpected failures.

Important Considerations in Electrical Maintenance

During electrical system maintenance in factories, anticipating potential failures for timely corrective action is crucial. Preparing spare materials and equipment for emergencies is essential. Planning upgrades or system conversions to meet new requirements and enhance performance should also be prioritized. Comprehensive training on technical and electrical safety for staff ensures effective and safe operations.

Electrical system maintenance is indispensable for ensuring efficient plant operations. Engineers need to conduct these vital steps to execute maintenance correctly.

Cause Assessment and Technical Preparation

- Identifying causes of malfunctions is critical before maintenance. This includes checking for current leakage, short circuits, or overload conditions.

- Completely disconnect power in the maintenance area to minimize risks and isolate personnel from the vicinity.

- Use protective gear like insulated gloves, safety shoes, and specialized measuring devices to ensure safety.

System Inspection

- Monitor and assess temperature and vibration in equipment to detect overheating or damage.

- Thoroughly check conductors and connections to avoid oxidation, looseness, or open circuits.

- Use measuring devices to check insulation resistance and identify current leaks to ensure technical safety.

Cleaning and Servicing

- Remove contaminants like dust and grease from equipment to prevent fire hazards.

- Lubricate mechanical parts such as circuit breakers and contactors to reduce friction and extend lifespan.

- Examine the surrounding environment, including humidity and temperature, to prevent impacts on equipment performance.

Replacement and Upgrades

- Prioritize replacing damaged components with products compliant with IEC or TCVN standards for safety and efficiency.

- Maintain detailed records of detected faults and solutions to optimize future maintenance scheduling.

- Update existing monitoring software to enhance accuracy in fault detection and resolution.

Safety and Compliance

- Strictly adhere to safety distance regulations when working with high voltage.

- Run no-load tests before reactivation to ensure safety.

- Regular and thorough staff training on new techniques and emergency handling.

Special Considerations

- Avoid using homemade devices to minimize repair risks.

- Ensure backup systems are in place to allow critical equipment to operate without interruption.

- Inspect lightning protection and grounding systems at least every six months for effectiveness.

Maintaining these systems requires advanced technical skills and thorough preparation to not only prevent potential failures but also ensure smooth operations and cost savings.

Challenges and Opportunities in Electrical System Maintenance

Maintaining industrial electrical systems not only optimizes performance and minimizes downtime but also ensures operator safety and long-term cost savings. This is an opportunity to integrate new technology, enhance efficiency, and improve all aspects of electrical systems.

In the modern industrial landscape, electrical system maintenance is pivotal in ensuring electrical system safety and optimization. Nevertheless, there are numerous challenges requiring particular attention from enterprises.

Challenges

- Technological Compatibility: A major challenge is ensuring that equipment and software within new technology systems are compatible. Ineffective resolution of incompatibilities can disrupt electrical monitoring and maintenance.

- Constant Technological Change: The rapid evolution of technology demands continuous updates in knowledge and skills, necessitating significant training investments by businesses.

- Labor Costs and Unexpected Failures: High labor costs and unforeseen failures can substantially increase the total costs of electrical system maintenance.

- Environmental and Safety Concerns: Inefficient maintenance can pose risks to worker safety and negatively affect the environment, particularly in relation to increased carbon emissions from delayed maintenance activities.

Opportunities

- Increased Productivity and Cost Savings: Employing new maintenance technologies allows for quicker problem identification and resolution, leading to maintenance cost savings and reduced downtime.

- Enhanced Safety: Modern electrical monitoring techniques offer safer procedures, reducing the risk of work-related accidents.

- Predictive Maintenance and Accident Mitigation: Advanced maintenance technologies enable accident predictions and prevention via data analysis, ensuring continuous electrical operations.

- Resource Optimization: Advanced maintenance systems can optimize resources, minimize waste, and boost overall efficiency.

In sum, while electrical system maintenance presents numerous challenges, adopting new technological solutions opens up significant opportunities for businesses to improve electrical performance and system safety.

New Technology Applications and the Future of Electrical Systems

Implementing new technologies like IoT for monitoring and analyzing industrial electrical system performance enhances maintenance processes. Now is the time to consider transitioning to renewable energy sources to lessen environmental impact and long-term costs.

New technological applications play a central role in transforming factory electrical systems. With flexible solution implementation, we have opportunities to optimize both costs and environmental effectiveness.

Flexible Electrical Technology

Research from Wärtsilä (2024) indicates that implementing flexible power plants in renewable energy-integrated systems (RES) could save up to €65 trillion by 2050. These plants not only enable rapid power adjustments to balance the electricity grid but also halve the need for new RES installations and occupied land area.

An essential electrical technology solution is real-time coordination systems, where high-speed control technology ensures RES equipment such as solar panels synchronize with storage systems (BESS), maintaining steady current/voltage.

Virtual Power Plant and Smart Grid

Virtual Power Plants (VPP) integrate distributed resources like rooftop solar panels, storage systems, and controllable loads to optimize supply-demand balance. VPPs enable rapid response services through controlling electric vehicle charging times or supplying reserve power during peak demand. This system also uses historical data to forecast RES production and optimize energy sources in real-time.

Industry 4.0 in Operational Management

IoT and automated monitoring systems provide superior connectivity and data analysis capabilities in electrical systems. IoT sensors collect voltage and load current data, transmitting it to the control center for analysis through big data analytics. System modeling helps assess and plan before actual deployment.

Future Trends

Future trends in electrical systems include the development of microgrids integrating renewable energy sources, where local systems autonomously manage energy through a combination of RES, storage, and backup generators. Additionally, self-healing systems become feasible via AI and intelligent switches, rapidly restoring power and automating incident responses.

Factory electrical systems are evolving due to:

- Multi-source integration providing flexibility in power generation,

- Data-driven optimization with IoT and AI support,

- Operational cost reduction through advanced storage technology and smart management models.

Maintaining industrial electrical systems not only ensures operational effectiveness but also offers significant technical and strategic advantages. The adoption of technology and process optimization lays a solid foundation for sustainable growth.

Contact QuangAnhcons today at Hotline: +84 9 1975 8191 for consultation on industrial electrical system maintenance solutions.

QuangAnhcons provides industrial electrical system maintenance services, guaranteeing continuous and safe operations while integrating advanced technology to enhance performance and sustainability.

[contact-form-7 id="7239967" title="Contact form 1"]

Related Posts

Tay Ninh Solar Power Planning: Technical Framework, Grid Interconnection, and Rollout Roadmap

Technical overview of solar planning in Tay Ninh: irradiation, grid capacity, permitting, design, operations, and [...]

Dec

Binh Duong Solar Planning: Regulatory Framework, Grid Interconnection, and an Implementation Roadmap for Factories and Industrial Parks

An overview of Binh Duong solar planning: legal framework, interconnection, design, risk management, and an [...]

Dec

Solar Farm Repair: O&M Workflow, IV Curve Diagnostics, Thermography, Inverter Service and Utility-Scale Safety

A utility-scale solar farm repair plan centered on O&M, IV curves, thermal imaging, inverter service, [...]

Dec

Dong Nai Solar Power Plan 2023–2025: Tri An 1,029 MW, Grid Upgrades and the DPPA Pathway

A complete look at Dong Nai’s solar power plan: Tri An 1,029 MW, irradiation potential, [...]

Nov

Quang Ngai Solar Power Plan 2024–2030: Legal Framework, Irradiance Potential, and Development Roadmap

A complete look at Quang Ngai’s solar power plan: capacity targets, irradiance (PVout), development zones, [...]

Nov

Solar Damage Assessment Services: On-Site Procedures, EL/IV/Thermography Testing & Compliance with Standards

Discover IEC/UL/NEC standard solar damage assessment processes: on-site evaluation, EL and IV curve testing, thermal [...]

Nov

Comprehensive Package Estimate for a 1800MVA 500kV Substation: Scope, Configuration 3x600MVA, Standards and Timeline Management

An overview of the 1800MVA 500kV substation estimate: construction scope, configuration 3x600MVA, GIS/AIS, SCADA, standards, [...]

Nov

Factory Electrical Systems: Comprehensive Design and Implementation Guide

Discover the detailed and safe process of factory electrical systems design and implementation. [...]

Oct

Blueprints Required for Factory Construction Permits

Discover the necessary blueprints in factory construction permit applications, from floor plans to electrical and [...]

Oct

What Are the Requirements for a Factory Construction Permit? A Comprehensive Guide

Explore the documentation and steps needed to secure a factory construction permit for streamlined project [...]

Oct

Factory Construction Permit Procedures in Vietnam: Essential Guidelines and Documents

Learn the procedures for securing a factory construction permit in Vietnam, focusing on document preparation [...]

Oct

Key Steps in the Factory Construction Process

Discover the essential steps and requirements for building factories. [...]

Oct

Comprehensive Electrical Substation Solutions by Quanganhcons

Discover the cutting-edge electrical substation solutions offered by Quanganhcons for industrial applications. [...]

Oct

Investment Costs for a 1MWp Solar Power System and Influencing Factors

Explore the investment costs for a 1MWp solar power system in Vietnam and the influencing [...]

Sep

QuangAnhcons: Elevating Wind Energy Solutions

Explore QuangAnhcons' leadership in wind energy and renewable solutions in Vietnam. [...]

Sep

Electrical Contractor Strategies at Becamex Industrial Park

Discover the strategic advancements and partnerships of the electrical contractor at Becamex Industrial Park. [...]

Sep

Investment Insights for 1MW Wind Energy in Vietnam: Costs and Opportunities

Discover the detailed analysis of costs and opportunities for investing in 1MW wind energy projects [...]

Sep

Advanced Electrical Installation Solutions by QuangAnhcons

Explore advanced electrical installation solutions and modern technology with QuangAnhcons. [...]

Sep

Enhancing Industrial Electrical Services with Quanganhcons

Discover Quanganhcons' expertise in industrial electrical services, offering efficient and sustainable power systems. [...]

Sep

Comprehensive MEP Solutions by QuangAnhcons: From Design to Maintenance Excellence

Discover optimal MEP solutions with QuangAnhcons, dedicated to excellence from design through maintenance. [...]

Sep