The dynamic demand for stable and efficient electricity underscores the importance of enhancing the grid with a 22KV transmission line and installing a 160kVA 22/0.4KV substation. This initiative is underscored by an intricate process of selecting superior materials and skilled labor to install a robust and efficient transmission system. It prioritizes adherence to avant-garde industrial standards and ensures effective collaboration with energy regulatory authorities. The detailed examination of this initiative will include a discussion on the selection of components, project execution techniques, financial management, customer service strategies, and compliance with regulatory mandates, offering a comprehensive insight into the undertaking.

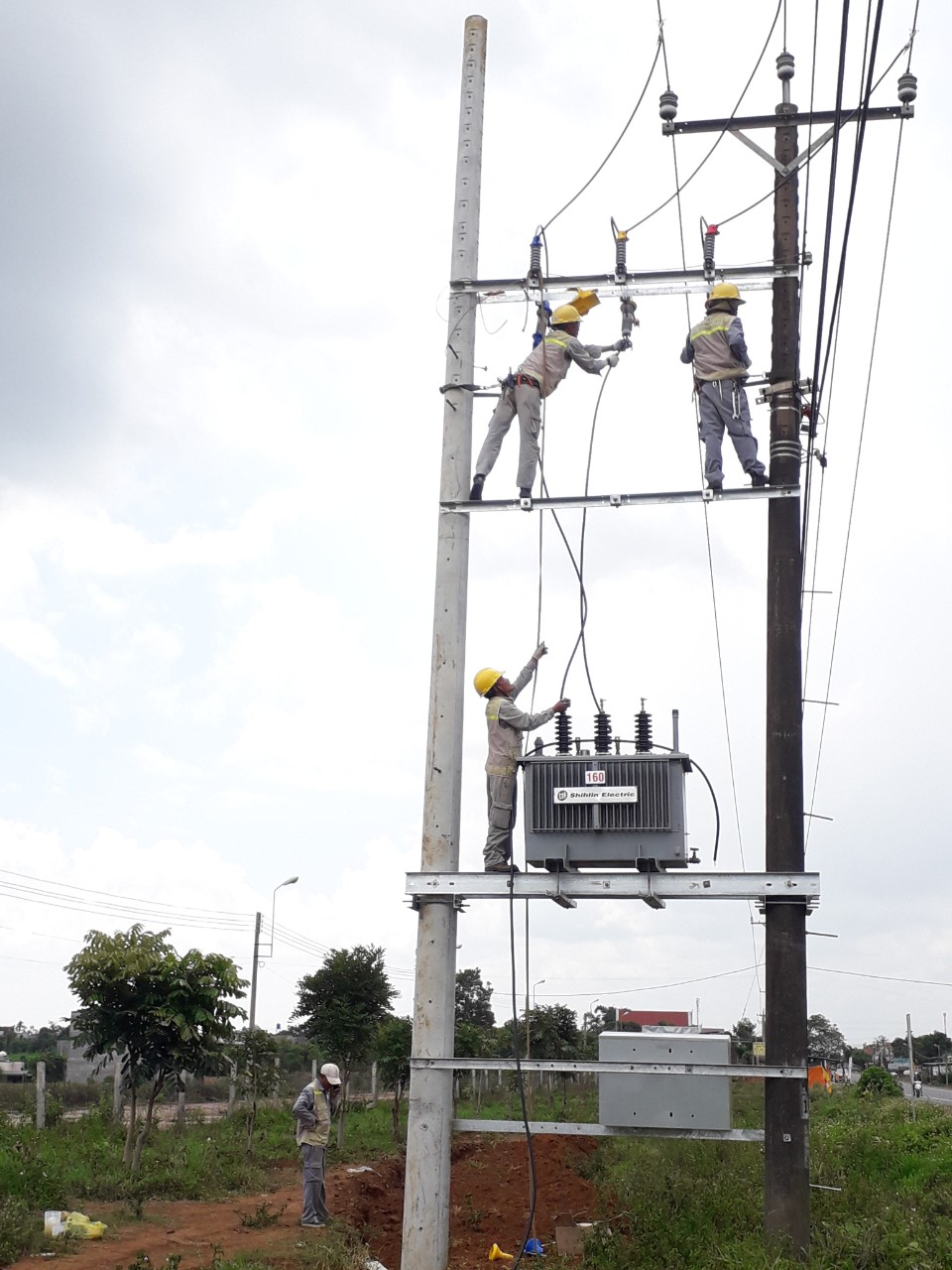

Constructing a transformer station is an important task that demands precision and in-depth technical knowledge. The 160KVA – 22/0.4kV transformer station plays a vital role not only in providing stable electrical power to residential areas and businesses but also affects the socio-economic development of the local area. Below is detailed information on the process of constructing a transformer station, from related documentation, preparation of materials and equipment, construction to warranty, helping our customers have the most comprehensive and detailed overview of this process.

I. Estimation of Materials and Equipment

1. 22kV Transmission Line:

– Materials and Equipment:

• 14m centrifugally spun concrete pole

• L2400x75x75x8mm/Zn iron brace

• 60x6x920/Zn bracing bar

• 24Kv standing insulator

• 24Kv polymer suspension insulator

• AXV 50mm2 insulated cable: phase conductor

• Bare AC 50mm2 cable: neutral conductor

• CXV 25mm2 insulated cable: Phase conductor

• FCO 200A-24kV polymer + base

• 20K lead wire

• Top and bottom FCO cap

• 2.4m composite brace + bracing bar

• 3P 4 wire 120/60V – 5A electronic meter

• Cu/XLPE/PVC 4Cx25mm2 cable – 0.6/1kV

• Composite electric meter cabinet sized H500 x W300 x D200

• Earth connection for the transmission line

• Pole foundation

• Transmission line testing

• Transmission line accessories

• Full package labor

2. 160KVA Substation:

– Materials and Equipment:

• 14m centrifugally spun concrete pole

• V75x75x8x2.6m iron brace, 2.4m hole center (3 covers, 80 cover, insulator + FCO mount)

• V75x75x8x2.6m iron brace, 2.4m hole center (no cover, MSB + compensation box mount)

• U-brace 100×0.5m

• U-brace 100×1.1m

• U-brace 200×2.8m (hole center 2.4m)

• 24kV standing Polymer Insulator DR600 + rod

• Substation accessories

• Centrifugally spun concrete pole foundation

3. 22kV Electrical Conduction and Low Voltage Conduction:

– Materials and Equipment:

• 24KV insulated C/XLPE/PVC 25mm² cable.

• CV/600V 150mm² and 95mm² cable output from transformer.

4. Equipment:

– Materials and Equipment:

• Oil transformer 3 Phase 160KVA- 22/0.4KV

• FCO 200A-24kV polymer + base

• 20K lead wire

• Top and bottom FCO cap

• 18KV 10KA LA

• Top and bottom LA cap

• 2 compartment MSB cabinet

• MCCB 3P 250A

• 80Kvar reactive power compensation

• PVC Pipe D114

• PVC Pipe bend D114

• PVC Pipe connector D114

• PVC Pipe collier clip D114

• Nameplates for FCO, pole, station, no climbing warning

• Substation earth connection

• Equipment testing

• Full package labor for the substation

– Costs and Percentage:

– Total cost of equipment: 9,183 USD, accounting for about 49.16% of the total project cost.

5. Other Costs:

• Design, estimation, appraisal costs

• Supervision costs

• Costs for electrical connection cut off

• Commissioning and completion costs

• Construction equipment & transportation of materials and equipment

II. Total Costs and VAT

In cost total, you can find all of the items mentioned above in our video.. The percentage of each part has been calculated based on the total project cost, providing an overview of the financial resource allocation for the construction of the 160KVA – 22/0.4kV transformer station.

Please note that the estimated prices for the 160kVA grid-type transformer station are for reference only. The actual cost will depend on the specific design of the transformer station as well as the materials and equipment used in the project. Additionally, exchange rates may fluctuate and the USD figures may need to be updated to current exchange rates to ensure the highest accuracy. To receive a detailed quote tailored to your specific needs, please contact us via our quote request form or call our hotline at (+84) 9 1975 8191 for the best advice.

III. Main Work Content

– Preparation and approval of technical drawings.

– Installation of a new metering system at the branch head of the station.

– Installation of a 250A MCCB control cabinet and an 80Kvar compensation cabinet to improve the power factor.

– Management of the entire process from permitting to electrical connection and commissioning.

IV. Timeline and Payment

The timeline for implementing the project is an important factor that determines the success and reliability of the service. For the construction of the 160KVA – 22/0.4kV transformer station, the preparation and organization time for construction is 30 days. The specific construction time is as follows:

– Preparation Time: During this phase, tasks such as planning, designing, preparing materials, and organizing the site will be carried out. The expected time to complete these stages is 30 days.

– Construction Time: Once all materials are ready, the construction of the transformer station begins and is expected to last for 15 days. This includes the installation and connection of the necessary equipment for the station to operate.

– Total Expected Duration: Combining both phases, the total time to complete the project is 45 days.

Regarding the payment method, the project is divided into three installments:

1. Installment 1: A 50% prepayment of the contract value immediately after the contract is signed by both parties. The contractor begins the electricity application procedures and installs materials and equipment.

2. Installment 2: An additional 40% of the contract value after the contractor has completed the installation of the transformer and carried out the necessary connections to complete the construction and prepare for energization and testing.

3. Installment 3: The remaining 10% of the contract value within 7 days from the date the contractor energizes the station.

V. Warranty & After-sales Service

We commit to a 12-month warranty for the entire transformer station, along with professional and prompt after-sales service. Any technical issues or faults will be dealt with swiftly and efficiently by our team, ensuring that your electrical system operates smoothly.

VI. Documentation and Procedures for Constructing a 160kVA Transformer Station

To construct a transformer station in Vietnam, a series of official procedures and regulations must be followed. Here is a summary of the necessary steps and documents required:

Preparation of Legal Documents and Paperwork: First, you need to prepare the legal documents including the land use right certificate (or land lease contract), business license, identification card (or passport) of the legal representative, environmental protection commitment (if any), each type with 4 notarized copies not older than 3 months.

Electricity Purchase Application/Request Letter: This is the first step in the procedure to apply for the installation of a transformer station. You need to submit an electricity purchase application at the local Power Company or the Business Department of the Vietnam Electricity Group.

Determination of the Electricity Purchase Location and Purpose of Use: As mentioned above, you need to provide a copy of the documents that determine the electricity purchase location (such as permanent residence book, house ownership certificate, house sale contract, etc.), ID card or passport of the legal representative and the purpose of using electricity at the location where the transformer station is to be built (such as business registration certificate or investment license).

Application for Connection According to the Regulations of the Ministry of Industry and Trade: Includes an application for connection, schematic diagrams of the main equipment after the connection point, and technical documents on the planned connection equipment.

Survey and Connection Agreement: After the Power Company receives the application, they will conduct a survey and negotiate with you on the location of the connection point and the technical requirements.

– Signing the Investment Contract and Carrying Out Legal Procedures: This includes agreements on conformity with the Electric Power Development Planning, obtaining construction permits, and planning for environmental protection.

– Execution of Construction and Building of the Station: Involves land clearance, application for excavation permits (if needed), procurement of materials and equipment, and organization of construction works.

– Acceptance and Energization: Upon completion, you must establish a commissioning board to conduct the acceptance and proceed with energization in the presence of the Power Company.

VII. Quotation and Service Provision

A 160kVA transformer station is not only a technical construction but also an essential part of the national electrical system. Smart investment and selection of a reputable construction partner will ensure energy security and contribute to the sustainable development of the community and business. Contact us today to start building your transformer station with the highest reliability and quality.

The process of building a 160KVA – 22/0.4kV transformer station requires attention to every detail, from selecting quality materials to managing the work progress tightly. With a clear plan and an experienced implementation team, our customers can be assured of a transformer station built to standards, ensuring safety and reliability for the electrical system.

Why Choose Us?

– Quality: All equipment and materials used in the construction of the transformer station are 100% new, genuine, with clear origin and reliable.

– Transparent Pricing: A detailed price list is provided in full, helping our customers understand all related costs.

– Experience: With many years of experience in constructing transformer stations across the country, we are confident in providing the best service.

– Prompt Support: Our customer support team is always ready 24/7 to answer any queries and provide technical support when needed.

For more information and specific advice on building a turnkey 160kVA 22/0.4kV transformer station, you can directly contact us through the information below. Our team of experts is always ready to assist you in planning, price appraisal, and handling all related legal procedures, ensuring a smooth and timely construction process.

Contact:

Quang Anh CE Co.,LTD

– Hotline: (+84) 9 1975 8191

– Email: project@quanganhcons.com

– Office:Unit 02, 08th floor, Pearl Plaza Building, 561A Dien Bien Phu Street, Ward 25, Binh Thanh District, Ho Chi Minh City

– Working hours: Monday to Friday, from 8:00 am to 5:00 pm.

Related Posts

Building a 7500KVA Substation: Costs, Timeline, and Project Management Insights

Building a 7500KVA – 22/0.4KV transformer substation requires intricate planning, specialized knowledge in electrical systems, [...]

Jun

Step-by-Step Costs for Constructing a 5000KVA Transformer Substation

Building a 5000KVA – 22/0.4KV transformer substation in Vietnam requires careful planning, deep expertise in [...]

Jun

Key Insights into Constructing a 4000KVA – 22/0.4KV Transformer Substation: Costs, Timeline, and Expertise

Constructing a transformer station is a pivotal task that demands meticulous planning, a robust understanding [...]

Jun

Investment Analysis for a 3200kVA Substation: Comprehensive Guide on Costs and Construction Timeline

The construction of a 3200kVA – 22/0.4kV substation is a sophisticated and detailed process that [...]

Jun

Key Steps and Costs in Building a 3000KVA – 22/0.4KV Substation

Constructing a large-scale transformer station such as the 3000KVA – 22/0.4KV is a significant project [...]

Jun

Detailed Pricing Guide for a 2500kVA Transformer Station Project

Comprehensive Guide to Constructing a 2500KVA Transformer Station in Vietnam Constructing a transformer station in [...]

Jun

How much is the full construction cost for a 1600kVA substation?

Constructing a transformer station is a technologically demanding endeavor that requires a deep understanding of [...]

Apr

What is the total construction price for a 2000kVA transformer substatation in Vietnam?

Comprehensive Guide to 2000kVA Substation Construction Costs in Vietnam 1.Detailed Costs Breakdown In the quest [...]

Apr

What is the total construction price for a 1500kVA substation in Vietnam?

Ensuring Quality and Compliance in Substation Construction Quality assurance and regulatory compliance are pillars of [...]

Apr

How much does it cost to build a complete 1250kVA substation in Vietnam?

The journey to erecting a transformer station is filled with intricate steps and rigorous standards. [...]

Apr

What is the all-inclusive construction cost for a 1000kVA transformer station in Vietnam?

Understanding the financial aspects of constructing a transformer station is crucial for any successful project. [...]

Apr

What is the total price for constructing an all-inclusive 800kVA substation in Vietnam?

Embarking on the construction of a 800kVA – 22/0.4KV substation requires a blend of detailed [...]

Apr

750kVA Substation – How much is the construction cost in Vietnam?

Constructing a transformer station is a complex and significant undertaking that requires careful planning, precision, [...]

Mar

How much is the total cost for constructing a 630kVA transformer station in Vietnam?

In the context where energy plays a pivotal role in socio-economic development and the demand [...]

Mar

Expert Construction of 560kVA Substations – Enhancing Electrical Distribution

As economies grow and the fabric of society becomes increasingly dependent on reliable energy, the [...]

Mar

How much does it cost to construct a 400kVA substation in Vietnam?

In an era where uninterrupted power supply forms the backbone of technological and economic advancements, [...]

Mar

Comprehensive Guide to 320kVA – 22/0.4KV Substation Construction

The necessity for a resilient and efficient power distribution system is ever-increasing in today’s fast-paced [...]

Mar

Comprehensive Guide to Constructing a 250kVA – 22/0.4kV Substation

In the quest to meet the growing demand for electricity in a sustainable and reliable [...]

Mar

Expert 180kVA – 22/0.4kV Substation Construction Services | Quang Anh CE

Addressing the critical need for dependable and efficient energy distribution, the project to introduce a [...]

Mar

How much does it cost to construct a 160KVA – 22/0.4kV substation in Vietnam?

The dynamic demand for stable and efficient electricity underscores the importance of enhancing the grid [...]

Mar